Application of Vacuum Precision Control - The Secret of Drying Fine Powder in Vacuum Oven

SHARE

MORE DETAIL

1. What is Vacuum Drying?

Vacuum drying is a drying method that puts materials under vacuum negative pressure conditions, and appropriately heats them to reach the boiling point under negative pressure, or cools down to make the materials solidify and then dry the materials through the melting point. Common dryer types mainly include tray, fluidized bed, spray, rotary, and vacuum oven dryers.

Vacuum drying process is carried out in a closed chamber connected to a vacuum pump, while vacuum oven uses the balance of temperature and vacuum pressure to reduce the humidity in chamber and product being dried. This technology is the most common laboratory, research and industrial drying for heat sensitive, hygroscopic or toxic powders and granules. For example, industries that commonly use dry powders include pharmaceuticals, food processing, plastics, and chemical processing.

For the vacuum drying of fine powder, one of the common problems is that no matter what type of drying equipment is adopted, the dry powder will accumulate into lumps or layers in various positions in dryer or in downstream process equipment such as vacuum pumps, thus affecting normal operation and service life of vacuum pump. Other potentially dangerous problems can arise if fine powder expelled from vacuum pump.

Recently, a vacuum oven manufacturer clearly proposed to upgrade the existing vacuum oven technology, and asked us to provide corresponding technical supporting measures to completely solve the above-mentioned problems in process of drying fine powder in vacuum oven. This article will introduce the corresponding solutions in detail. The core of solution is to reach the controlled discharge of vacuum oven, so that vacuum degree of oven has a slow and controllable change process. This article also introduces in detail the key technical parameters and functions of the corresponding supporting devices in the solution.

2. How to solve the problem of Vacuum Drying?

In the process of vacuum drying fine powder without dust and accumulation, two measures need to be taken:

- Emission control: Lead a small amount of dry air or nitrogen into vacuum box to remove water vapor in box, and also heat it at the same time, so that cycle flushing through exhaust/intake will help to speed up drying process. However, when drying fine powder, if exhaust is not controlled, the process can also wash away it, so a precise and controllable exhaust valve is used to control exhaust flow.

- Vacuum control: The change of vacuum degree in drying process must be precise and controllable, especially as drying time prolongs, the change of vacuum degree should be slower to avoid possible dust generation and being brought into air outside dryer.

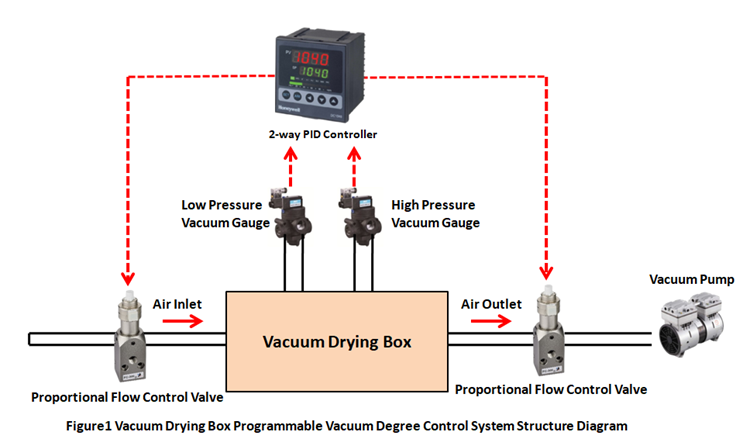

It can be seen that the key to solving problem of vacuum drying of fine powder is to reach the program control of vacuum degree. The vacuum degree control program includes two types: linear change and constant, and control program can be set arbitrarily, so that various vacuum drying processes can be carried out. The technical transformation plan of vacuum oven designed according to the idea of vacuum program control is shown in Figure 1. The entire vacuum control system mainly includes KaoLu's Proportional Flow Control Valve, vacuum gauge, programmable PID controller and vacuum pump, PID controller to adjust the opening of KaoLu's Proportional Flow Control Valve respectively to reach the change of vacuum degree in box according to set procedure.

For the vacuum degree control of fine powder drying process, the key is to make vacuum degree change according to a certain set rate, which will change vacuum degree in oven from atmospheric pressure to air pressure in a long period of time (such as 10-20 minutes) and slowly reduce to desired low pressure. The so-called rate is amount of change per unit time, such as slope of 10Torr /min means that vacuum degree changes gradually by 10Torr within 1 minute.

For a dry powder process of one of our customers, they chose a depressurization rate of about -150Torr/min. They would start at 750 Torr, and pressure would go to 600 Torr about one minute. Then the next minute to 450 Torr until they reached their set target pressure. After the target pressure is reached, automatic constant control can also be continued at target pressure. In this way, through this automatic vacuum control method, it can be

This vacuum degree control system for fine powder drying process has the following characteristics:

- Ordinary fine powder drying process does not have very high requirements on final vacuum degree, and the range of vacuum degree is generally only in the range of 10Torr~1 atmospheric pressure. At this time, the vacuum degree control system only needs to be equipped with a vacuum gauge when it covers the required pressure range.

If it is required to dry under a higher vacuum degree, such as 0.1Torr~1 atmospheric pressure range, as shown in Figure 1, the control system needs to be equipped with two vacuum gauges to reach precise measurement and control of the full-scale vacuum degree. - The vacuum degree controller used is a high-precision dual-channel controller, and each channel has an independent PID automatic control function. Each channel is 24-bit AD and 16-bit DA, double precision floating point operation and minimum output percentage is 0.01%. The controller has RS485 communication and standard MODBUS protocol, equipped with measurement and control software, which can be remotely operated and stored to display test curves.

- In vacuum degree control system as shown in Figure 1, KaoLu's Proportional Flow Control Valve is equipped at air inlet and outlet respectively, and controller automatically adjusts opening of Proportional Flow Control Valve to reach precise control of vacuum degree. In vacuum degree control process of low pressure range, KaoLu's Proportional Flow Control Valve responsible for downstream exhaust is generally adjusted to be fully open all the time.

Vacuum degree control is reached by adjusting air intake flow through Proportional Flow Control Valve. In vacuum degree control process of high pressure range, KaoLu's Proportional Flow Control Valve responsible for upstream air intake is adjusted to a certain opening and kept constant, and exhaust flow is adjusted through downstream Proportional Flow Control Valve to reach vacuum control.

In addition, KaoLu's Proportional Flow Control Valve equipped here are all high-speed valves, and the time from fully closed to fully opened is less than 1 second, which is very suitable for dynamic control of vacuum degree. The use of 0~10V or 4~20mA analog signals can directly driven, and KaoLu's Proportional Flow Control Valve has a low vacuum leakage rate, which is suitable for high vacuum requirements of various closed equipment.

To sum up, the programmable vacuum degree control solution described in this article is highly mature in technology. After a large number of experiments, the feasibility and reliability of this solution have been verified. The vacuum degree control accuracy can easily reach within ±1%, which can be completely solve the problem of dust and fouling caused by drying fine powder in vacuum oven, this solution has also been applied in many other vacuum equipment and processes.

For further information about KaoLu's Proportional Flow Control Valve, please refer to our website.