Product Category Selection

Proportional Electronic Pressure Regulator Working Principle

Our electronically controlled pressure regulator is a complete closed-loop servo system consisting of two solenoid valves, an internal pressure transducer, and electronic controls. Based on analog signals, the pressure is controlled by two solenoid valves to maintain precise pressure; one valve functions as inlet control, the other as exhaust. The pressure output is measured by an internal or an external feedback pressure transducer that provides a feedback signal to the electronic controls. Our product of electro pneumatic regulator features high speed, high pressure, and high resolution.

Selections of Electronic Regulators:

https://www.genndih.com/Proportional-Pressure-Regulator/High-Speed-Proportional-Regulator

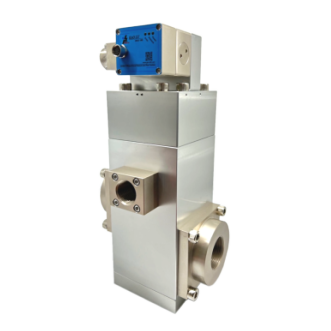

QKL-HS series are 3-way electronic pressure regulators. It consists of proportional solenoid, pressure transducer, intelligent electronics, and a refined spool. It features high flow rate, extremely fast pressure switching time, high accuracy, and compatible with oxygen and hydrogen gas. Using the powerful in-house software, the control parameter can be customized that allows user to build unique pressure profile. It is available with analogue and digital command signal. HS series electronically controlled pressure regulator can be used in demanding environment and is compatible with oxygen, hydrogen, and helium gas.

FAQ session – Proportional Electronic/Digital Pressure Regulators

- What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge?

They are the same products with different names. - Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc.

- Is the pressure regulator resistant to dirt?

No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. - Any restriction on mounting orientation?

Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag.

Knowledge Base

How Does a Proportional Pressure Regulator Work?

A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control.

Uses of Regulators

Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications.

The Working Process:

Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static.

When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal.

Please check our video on: GennDih Enterprise. Co. Ltd

Low Pressure Proportional Regulator (0-8bar)

The low pressure proportional pressure regulator can be categorised into

1. low flow

2. high flow

3. economic type

The low flow rate version is ideal for regulating air pressure in a small closed volume, applications include mini cylinder and microfluidics.

The high flow rate version is suitable for dynamic process condition or regulating pressure in a bigger volume container.

The economic type has accuracy of 0.5% F.S, it is also suitable for dynamic process, it is suitable for low pressure control in laser cutting machine.

Medium Pressure Proportional Regulator (0-30bar)

Series QKL-B1S high pressure low flow electro-pneumatic pressure regulator allows pressure control up to 30 bar ( 435 psi), maximum inlet pressure at 34 bar ( 493 psi). Works in both static or dynamic flow condition without pressure droop.

Resolution can reach up to 5mV. Takes 0-10V, 4-20mA or RS485 signal. Series QKL-B3H I/P transducer provides high pressure high flow version, with flow rate up to 6000 L/min (212 scfm). It is able to reach low pressure in quick response time. Provides feedback signal to monitor pressure output. It is possible to customise pressure range, consult factory for customization.

High Pressure Proportional Regulator/ Controller (0-70bar)

Kaolu's 70 bar (1015 psi) electronic air pressure regulator provides precision electronic control of pneumatic pressure from 0 to 70 bar. With flow rate up to 170 L/min, it can be used in both static and dynamic conditions.

This series of I/P transducer can reach accuracy up to 0.25% F.S. Takes 0-10V or 4-20mA signal, and provides feedback signal of 0-10V or 4-20mA. It is possible to customise maximum pressure range, consult factory for customization. It is often used to replace GX series pressure control valve.

Electronic Vacuum Regulator (0~ -101kpa)

QKL-B3V electronic vacuum regulator

Allows user to regulate vacuum level via analog or digital control signal. The regulator is self-relief, meaning that it will exhaust excess air to reach target vacuum level. The monitor output is available either as analog output or switch output.

QKL-B3V is IP65 equivalent.

Vacuum set pressure: 0 to -14 psi

Power supply voltage: 24 VDC ± 10%

Connector: M12

Linearity: ± 0.3% F.S.

Hysteresis: ± 0.25% F.S.

Repeatability: ± 0.3% F.S.

Accuracy: ±0.3% F.S.

Enclosure rating: IP65

Flow Rate: 250~600 L/min

Port: G 1/4"

Ultra High Resolution Proportional Pressure Regulator

Electronic pressure regulator is an ideal solution for digitally regulating air pressure in industrial automation and process line.

QKL high resolution provides ultra resolution in cases where fine tuning of pressure is required, such as in various semiconductor manufacturing applications.

Steam, Water Proportional Pressure Regulator

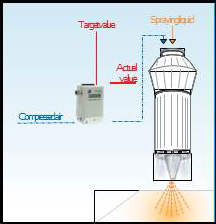

This Proportional Pressure Regulator provides pilot pressure to the ratio relay volume booster.

By controlling pilot pressure at the top of the diaphragm, we can control the output pressure of volume booster.

High Flow with Volume Booster (0-10bar)

QKL-B1T + Type600 volume booster

Resolution up to 0.01 psig, flow rate up to 4200 L/min.

Suitable for use in ultra-precision equipment, or places require high flow rate dynamic pressure regulation. QKL-B1T electronic pressure regulator can be controlled by analogue or digital signal to dynamically and swiftly regulate air pressure. It is suitable to provide pilot pressure to a dome loaded volume booster or pressure booster.

Type 600 is a high resolution, high flow volume booster. The output pressure is regulated by the pilot electronic pressure regulator.

The flow can be amplified in different ratio. This combination of electronic pressure regulator and volume booster meets the requirements where high flow and high resolution of pressure control is needed.

Electronic Pressure Regulator (0-100bar)

Kaolu's 105 bar (1523 psi) electronic air pressure regulator provides precision electronic control of pneumatic pressure from 0 to 100 bar. With flow rate up to 140 L/min, it can be used in both static and dynamic conditions.

This series of I/P transducer can reach accuracy up to 0.01% F.S. Takes 0-10V or 4-20mA signal, and provides feedback signal of 0-10V or 4-20mA. It is possible to customise maximum pressure range, consult factory for customization. It is often used to replace GX series pressure control valve.

Air Pressure Ratio Regulator (0-103bar)

KaoLu's high resolution electronic pressure regulator is capable of outputting pressure up to 40 times of set pressure. With a set pressure between 0 to 5 bar (0 to 72.5 psig), the users can tune output pressure up to 100 bar (1450 psig) or even up to 210 bar (3000 psig).

The strong feature of our ratio regulator is that it won't sacrifice repeatability and accuracy, we can still manage the resolution/sensitivity up to 0.3 bar (5 psig), which means a turndown ratio up to 1: 420.

Moreover, not only our air pressure ratio regulator can control the pressure of air, our newly developed ratio regulator also regulates different fluid such as water and steam.

Product Description

The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation.

Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design.

For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc.

Applications for Electronic Pressure Regulators

Spraying/ Painting

Air Blowing

Leak Testing

Filling Pressure

Artificial Heart

Laser Cutting