SHARE

MORE DETAIL

Solution of Vacuum Precision Control in Drying Process of Temperature Sensitive Materials

Abstract: Nowadays, some vacuum drying ovens that we often used are equipped with digital temperature control, but basically use manual vacuum control valves. In response to some customers' requirements for upgrading and transforming the automatic vacuum control of the drying oven, this article introduces the vacuum precision control solution. The solution introduces several different control methods in detail, and also includes solutions for simultaneous control of temperature and vacuum to meet the automation control needs of different customers' vacuum drying equipment.

1. Introduction

Temperature-sensitive materials are a class of materials whose physical properties change dramatically and discontinuously with temperature. Drying of temperature-sensitive materials is required in many different industries, such as various additive manufacturing, life sciences, tissue engineering, liquid chromatography, drug delivery, and research and development. Other temperature-sensitive materials include fruits, vegetables and other plants. The ideal method for drying heat- and/or oxygen-sensitive materials is vacuum drying, as it has the advantage of removing moisture at lower temperatures and minimizing possible oxidation reactions. In addition, vacuum drying has the advantage of faster drying and can be performed in an oxygen-deficient processing environment.

The drying of temperature-sensitive materials needs to be carried out in a vacuum drying device. In order to avoid damage to product, it is necessary to precisely control the temperature and vacuum degree in vacuum drying device. The vacuum degree control is particularly important, because it is based on the principle of saturated vapor pressure. In the vacuum drying process, the degree of vacuum determines the upper limit of evaporation temperature of water.

At present, some commonly used vacuum drying ovens are equipped with digital temperature control, but basically use manual vacuum control valve. In response to some customers' requirements for upgrading the automatic vacuum control of drying oven, this article will introduce the vacuum precision control solution. The solution introduces several different control methods in detail, and also includes solutions for simultaneous control of temperature and vacuum to meet the automation control needs of different customers' vacuum drying equipment. Customized solutions to meet the automation control needs of different customers' vacuum drying equipment.

2. Technical Scheme

There are many forms of vacuum drying process and equipment, which can be summarized into the following three types:

(1) Closed cavity type.

(2) Fill with inert gas.

(3) Containers of different volumes.

For the above-mentioned types of vacuum drying devices, corresponding vacuum degree control devices need to be used.

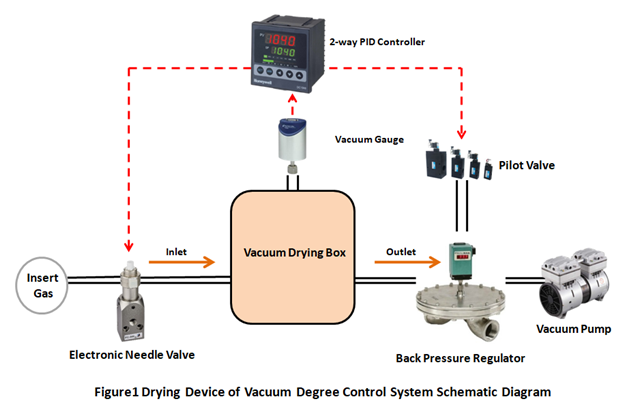

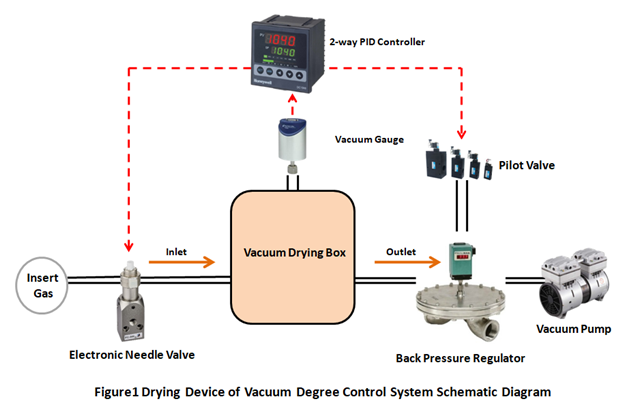

The solution proposed in this article is shown in Figure 1. The selection of the corresponding components in this solution can fully meet the needs of the above-mentioned several types of vacuum drying devices. The different types of controls would be described in detail below.

2.1 Pressure regulation method of closed cavity

For vacuum drying equipment with a closed cavity structure, the precise control of vacuum degree inside the drying equipment can be reached directly by controlling the pressure. The specific pressure control device is only connected to the right part of drying box in Figure 1 (back pressure regulator and vacuum pump), and uses an external vacuum gauge combined with a PID controller to adjust the degree of vacuum.

The back pressure regulator is a vacuum type of back pressure regulator, and the vacuum back pressure regulator is driven by an electric proportional valve. The external vacuum gauge, PID controller and electric proportional valve form a closed-loop control loop, so that the vacuum degree in drying box can be controlled according to any set value, and the vacuum degree curve can also be controlled according to the set program.

2.1 Pressure regulation method of closed cavity

For vacuum drying equipment with a closed cavity structure, the precise control of vacuum degree inside the drying equipment can be achieved directly by controlling the pressure. The specific pressure control device is only connected to the right part of the drying box in Figure 1 (back pressure valve and vacuum pump), and uses an external vacuum gauge combined with a PID controller to adjust the degree of vacuum.

The back pressure valve is a vacuum type back pressure valve, and the vacuum back pressure valve is driven by an electric proportional valve. The external vacuum gauge, PID controller and electric proportional valve form a closed-loop control loop, so that the vacuum degree in the drying box can be controlled according to any set value, and the vacuum degree curve can also be controlled according to the set program.

2.2 The flow adjustment method of the inflation process

For the vacuum drying of some oxygen-sensitive materials, it is necessary to fill in an inert gas for oxygen replacement sometimes. In this case, the control of vacuum degree of drying box needs to adjust the intake and exhaust flow to reach dynamic balance. At this time, the entire vacuum degree control system structure is completely shown in Figure 1.

As shown in Figure 1, the air intake flow is adjusted by an electric needle valve, and the outgoing air flow can be adjusted by a vacuum back pressure valve or an electric ball valve (not shown in the figure). The adjustment of air flow in and out is reached by a closed loop composed of a vacuum gauge and a 2-channel PID controller. Similarly, the vacuum degree in the drying box can be controlled according to any set value, and the vacuum degree curve control can also be performed according to the set program.

2.3 Large-diameter pressure regulating regulator method for large-sized cavity

For some large-sized chambers for vacuum drying of large-volume products, the key point to vacuum degree control is to use a large-diameter regulating regulator, that is, the vacuum back pressure valve (or electric ball valve and electric butterfly valve) in Figure 1 requires a larger diameter in order to reach rapid control of large pumping speed and vacuum degree. At present, the technology of various large-diameter control valves has matured and there are standard products.

2.4 Simultaneous control method of temperature and vacuum degree

For most vacuum drying equipment, two variables, temperature and vacuum degree, need to be controlled at the same time. In the technical solution proposed in this article, a 2-channel high-precision PID controller is used, and two channels can be used to control temperature and vacuum degree at the same time, that is, two independent closed-loop loops are formed by connecting the temperature sensor and the vacuum degree sensor to control.

In addition to the 0-10V voltage signal output by vacuum sensor, the two-channel PID controller can also be connected to the input signal of various temperature sensors (thermocouple, platinum resistance, thermistor, etc.). Especially using 24-bit A/D analog-to-digital and 16-bit D/A digital-to-analog converter, this two-channel PID controller can reach high control accuracy.

3. Summary

Through the above technical solutions, the requirements for automatic control of temperature and vacuum degree in the drying process of temperature-sensitive materials can be fully met, and high control accuracy can be reached (absolute pressure 10Pa - 0.1MPa, control accuracy better than 2%).

Are you interested in KaoLu's Proportional Flow Control Valve? You can feel free to visit our website!

Abstract: Nowadays, some vacuum drying ovens that we often used are equipped with digital temperature control, but basically use manual vacuum control valves. In response to some customers' requirements for upgrading and transforming the automatic vacuum control of the drying oven, this article introduces the vacuum precision control solution. The solution introduces several different control methods in detail, and also includes solutions for simultaneous control of temperature and vacuum to meet the automation control needs of different customers' vacuum drying equipment.

1. Introduction

Temperature-sensitive materials are a class of materials whose physical properties change dramatically and discontinuously with temperature. Drying of temperature-sensitive materials is required in many different industries, such as various additive manufacturing, life sciences, tissue engineering, liquid chromatography, drug delivery, and research and development. Other temperature-sensitive materials include fruits, vegetables and other plants. The ideal method for drying heat- and/or oxygen-sensitive materials is vacuum drying, as it has the advantage of removing moisture at lower temperatures and minimizing possible oxidation reactions. In addition, vacuum drying has the advantage of faster drying and can be performed in an oxygen-deficient processing environment.

The drying of temperature-sensitive materials needs to be carried out in a vacuum drying device. In order to avoid damage to product, it is necessary to precisely control the temperature and vacuum degree in vacuum drying device. The vacuum degree control is particularly important, because it is based on the principle of saturated vapor pressure. In the vacuum drying process, the degree of vacuum determines the upper limit of evaporation temperature of water.

At present, some commonly used vacuum drying ovens are equipped with digital temperature control, but basically use manual vacuum control valve. In response to some customers' requirements for upgrading the automatic vacuum control of drying oven, this article will introduce the vacuum precision control solution. The solution introduces several different control methods in detail, and also includes solutions for simultaneous control of temperature and vacuum to meet the automation control needs of different customers' vacuum drying equipment. Customized solutions to meet the automation control needs of different customers' vacuum drying equipment.

2. Technical Scheme

There are many forms of vacuum drying process and equipment, which can be summarized into the following three types:

(1) Closed cavity type.

(2) Fill with inert gas.

(3) Containers of different volumes.

For the above-mentioned types of vacuum drying devices, corresponding vacuum degree control devices need to be used.

The solution proposed in this article is shown in Figure 1. The selection of the corresponding components in this solution can fully meet the needs of the above-mentioned several types of vacuum drying devices. The different types of controls would be described in detail below.

2.1 Pressure regulation method of closed cavity

For vacuum drying equipment with a closed cavity structure, the precise control of vacuum degree inside the drying equipment can be reached directly by controlling the pressure. The specific pressure control device is only connected to the right part of drying box in Figure 1 (back pressure regulator and vacuum pump), and uses an external vacuum gauge combined with a PID controller to adjust the degree of vacuum.

The back pressure regulator is a vacuum type of back pressure regulator, and the vacuum back pressure regulator is driven by an electric proportional valve. The external vacuum gauge, PID controller and electric proportional valve form a closed-loop control loop, so that the vacuum degree in drying box can be controlled according to any set value, and the vacuum degree curve can also be controlled according to the set program.

2.1 Pressure regulation method of closed cavity

For vacuum drying equipment with a closed cavity structure, the precise control of vacuum degree inside the drying equipment can be achieved directly by controlling the pressure. The specific pressure control device is only connected to the right part of the drying box in Figure 1 (back pressure valve and vacuum pump), and uses an external vacuum gauge combined with a PID controller to adjust the degree of vacuum.

The back pressure valve is a vacuum type back pressure valve, and the vacuum back pressure valve is driven by an electric proportional valve. The external vacuum gauge, PID controller and electric proportional valve form a closed-loop control loop, so that the vacuum degree in the drying box can be controlled according to any set value, and the vacuum degree curve can also be controlled according to the set program.

2.2 The flow adjustment method of the inflation process

For the vacuum drying of some oxygen-sensitive materials, it is necessary to fill in an inert gas for oxygen replacement sometimes. In this case, the control of vacuum degree of drying box needs to adjust the intake and exhaust flow to reach dynamic balance. At this time, the entire vacuum degree control system structure is completely shown in Figure 1.

As shown in Figure 1, the air intake flow is adjusted by an electric needle valve, and the outgoing air flow can be adjusted by a vacuum back pressure valve or an electric ball valve (not shown in the figure). The adjustment of air flow in and out is reached by a closed loop composed of a vacuum gauge and a 2-channel PID controller. Similarly, the vacuum degree in the drying box can be controlled according to any set value, and the vacuum degree curve control can also be performed according to the set program.

2.3 Large-diameter pressure regulating regulator method for large-sized cavity

For some large-sized chambers for vacuum drying of large-volume products, the key point to vacuum degree control is to use a large-diameter regulating regulator, that is, the vacuum back pressure valve (or electric ball valve and electric butterfly valve) in Figure 1 requires a larger diameter in order to reach rapid control of large pumping speed and vacuum degree. At present, the technology of various large-diameter control valves has matured and there are standard products.

2.4 Simultaneous control method of temperature and vacuum degree

For most vacuum drying equipment, two variables, temperature and vacuum degree, need to be controlled at the same time. In the technical solution proposed in this article, a 2-channel high-precision PID controller is used, and two channels can be used to control temperature and vacuum degree at the same time, that is, two independent closed-loop loops are formed by connecting the temperature sensor and the vacuum degree sensor to control.

In addition to the 0-10V voltage signal output by vacuum sensor, the two-channel PID controller can also be connected to the input signal of various temperature sensors (thermocouple, platinum resistance, thermistor, etc.). Especially using 24-bit A/D analog-to-digital and 16-bit D/A digital-to-analog converter, this two-channel PID controller can reach high control accuracy.

3. Summary

Through the above technical solutions, the requirements for automatic control of temperature and vacuum degree in the drying process of temperature-sensitive materials can be fully met, and high control accuracy can be reached (absolute pressure 10Pa - 0.1MPa, control accuracy better than 2%).

Are you interested in KaoLu's Proportional Flow Control Valve? You can feel free to visit our website!