SHARE

MORE DETAIL

At present, silicon solar cells occupy most market of photovoltaic power, and are very important in terms of efficiency improvement and cost control. As an important part of silicon battery production, the screen printing of silicon battery electrodes directly affects the competitiveness of screen printing equipment in the market on the accuracy, efficiency and cost of printing equipment.

Screen printing is to attach a stencil with an image or a pattern to the screen for printing. When the substrate is placed directly under the screen with the stencil, the screen printing ink or paint passes through the extrusion of the squeegee. The mesh in the middle of the screen is printed on the carrier. One of the most important steps is the precision and pressure of the squeegee drop, which directly affects the layer thickness and shape of the printing, and even causes the silicon wafer to be damaged because the drop distance of the squeegee is too large. Therefore, the control of the squeegee is an important part of screen printing. The proportional pressure valve manufactured by KaoLu provides a comprehensive solution for screen printing equipment manufacturers with the advantages of high precision and high response.

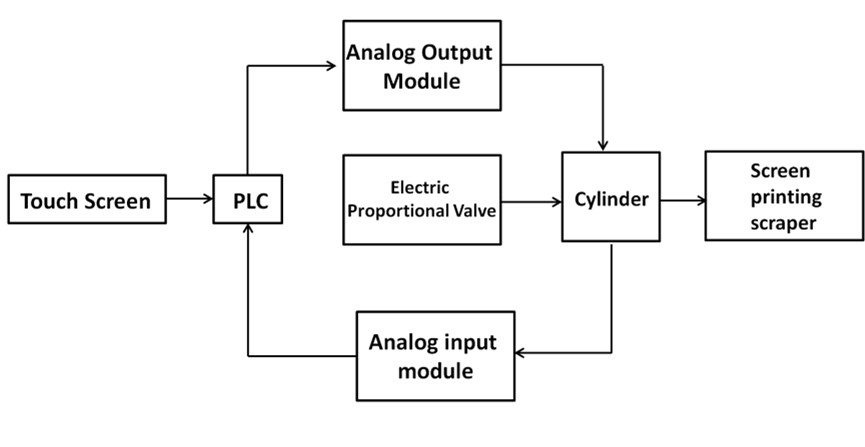

KaoLu’s electronic air pressure regulator controls the corresponding pressure by controlling the input signal, and the output controls the corresponding movement of the cylinder to push the scraper speed to accurately drop to the required height, and transmit it to the controller in real time through the feedback signal. This is a method of pre-calculating the electronic air pressure regulator, which uses the linear characteristics of the electronic air pressure regulator to accurately control the pressure of screen printing blade to meet the accuracy required by the power system of screen printing machine. KaoLu’s electronic air pressure regulator adopts new technology, which enables it to achieve high control accuracy, and is widely used in the printing industry at present. KaoLu’s electronic air pressure regulator uses pneumatic components and semiconductor sensors to improve accuracy and response by adjusting the proportional pressure signal. The pressure control system of screen printing machine is composed of a electronic air pressure regulator, a screen printing scraper, a touch screen, a cylinder and a programmable logic controller. The schematic diagram is as follows:

Set the working pressure of silk screen scraper on the touch screen, the PLC controller will calculate and convert it into the digital quantity required by the analog output module, and the analog output module will output a certain voltage value to the proportional pressure valve. The electronic air pressure regulator will output the pressure according to the voltage signal, and the internal pressure sensor detects that the set pressure value is reached, that is, the pressure adjustment is completed.

Proportional pressure valves are not only used in the screen printing machine industry, but KaoLu’s electronic air pressure regulator can be widely used in industrial applications, automotive industry, inkjet industry and blow molding industry.

If you have any needs or questions, please subscribe to our YouTube channel or contact us to learn more about proportional pressure valves.

https://www.genndih.com