SHARE

MORE DETAIL

Application of solenoid valve in automatic transmission

When it comes to automatic transmission, its driving convenience, power and comfort are more and more approved by consumers. The working principle and components of automatic transmission have also attracted more attention. The application of solenoid valve in automatic transmissions will be introduced in this article.

Hydraulics and solenoid valves in automatic transmissions

No matter it is a DCT, AT or CVT automatic transmission, the mainstream technical solutions are indispensable to the hydraulic system. The hydraulic system accepts the signal from controller, outputs oil pressure or flow, and acts on the actuator. The functions of hydraulic system mainly include: controlling the clutch, synchronizer or band pulley to reach the change of transmission ratio, controlling the state of torque converter clutch, and controlling the cooling and lubrication of the system. The performance of hydraulic system directly affects the smoothness of shifting and fuel economy of the entire vehicle, and is an important part of automatic transmission.

In the hydraulic system, the solenoid valve, which as an actuator, reaches the transformation from electrical signals to hydraulic signals, and controls the pressure and flow in the hydraulic system. It is a key component in the hydraulic system.

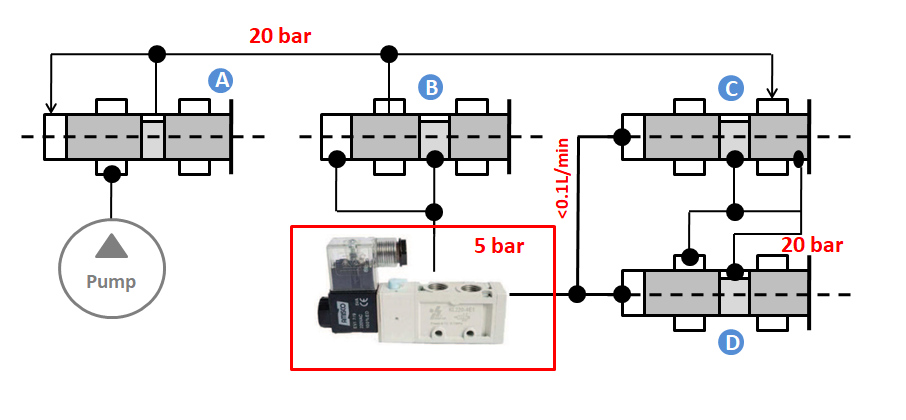

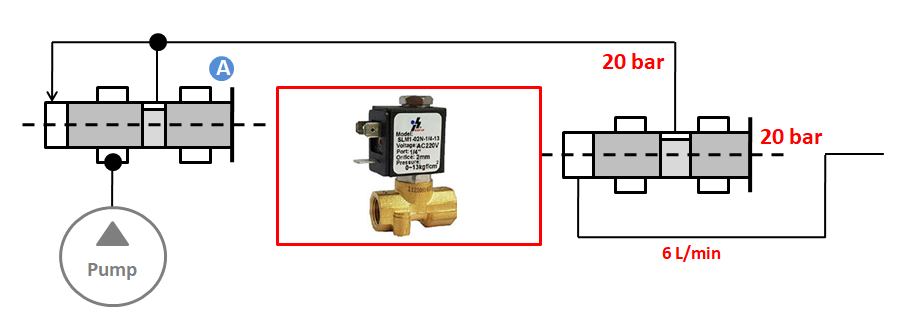

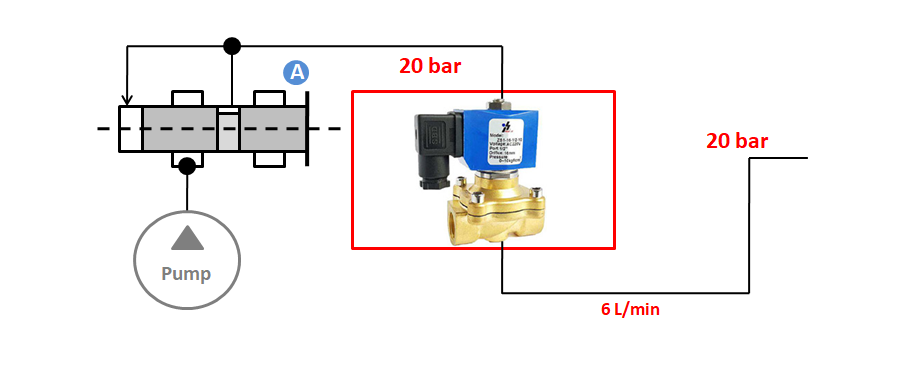

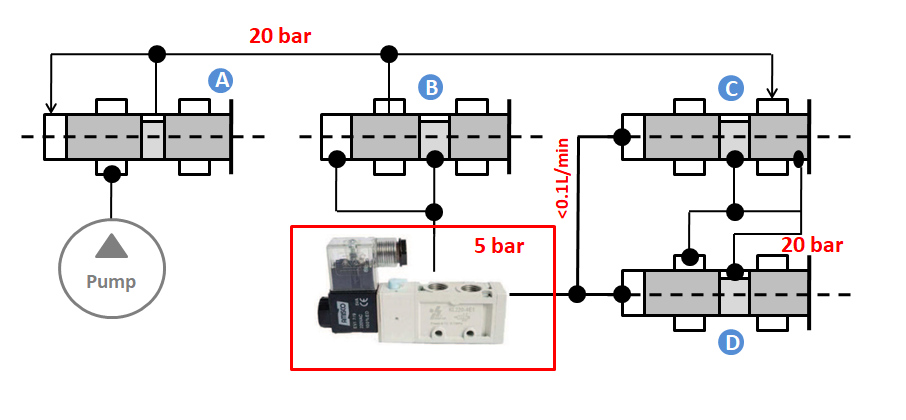

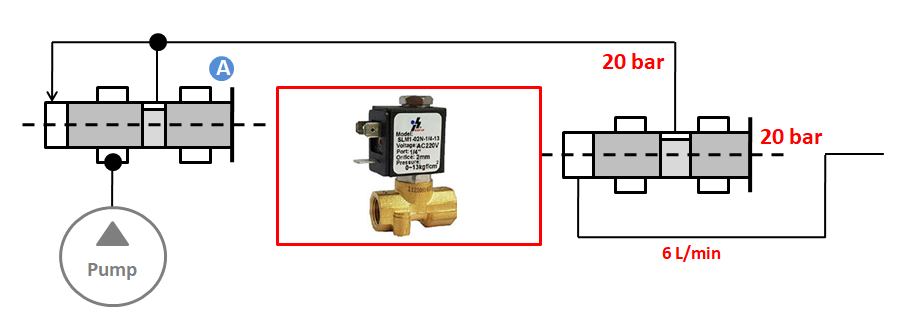

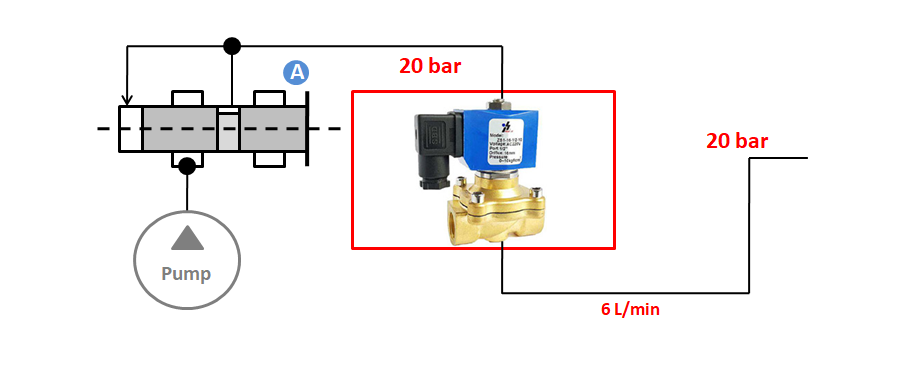

Classification and application of solenoid valve

The solenoid valve is divided into pilot control and direct drive control in the hydraulic system. The control pressure and flow of the pilot solenoid valve are relatively low, and the actuator cannot be directly driven, only the pilot control pressure is provided. The direct-drive solenoid valve has a larger electromagnetic force than the pilot valve, and control pressure and flow can directly drive the actuator. The hydraulic system using the direct-drive solenoid valve reduces the number of mechanical valves and simplifies the structure of system. Another solenoid valve product is the proportional electromagnet. Compared with other solenoid valves, the proportional electromagnet only has the electromagnetic part, which provides electromagnetic force. The hydraulic part is integrated on the hydraulic valve body. It is designed by customers according to the needs of the specific system. It has higher flexibility, but at the same time increases the integration difficulty of the hydraulic system.

Pilot control method: → Standard solenoid valve + mechanical valve

Advantage: Strong robustness

Disadvantage: 1. Many valves 2. Complex structure of system

Direct drive electromagnet control method: → Direct drive electromagnet + mechanical valve

Advantage: High flexibility

Disadvantage: Difficult integration

Direct drive electromagnet control method: → Solenoid valve drive actuator directly

Advantage: 1. Simple structure of system 2. High precision

Disadvantage: High cost

The introduction of proportional pressure regulator

Bleed type valve:

As shown in the figure below, the valve core is affected by hydraulic pressure, spring force and electromagnetic force. The balance state determines the valve core position, thereby determining the area of drain port. The pressure of control chamber at the left end depends on the input pressure, the input orifice and the area of the drain port determined by the variable adjustment surface. Therefore, the bleed valve achieves the effect of controlling the pressure by controlling the electromagnetic force. Since the Bleed valve regulates the pressure through overflow, the leakage of this valve is relatively large, and the control pressure is more sensitive to the fluctuation of input pressure.

Spool type pressure valve:

As shown in the figure below, ignoring the influence of hydraulic power, the spool of

pressure valve is affected by the spring force, electromagnetic force and hydraulic

feedback force. Under the stable condition, the spool is in a balanced condition. The

electromagnetic force is positively related to the control current of solenoid valve.

Since the characteristics of the spring are fixed, in equilibrium, the electromagnetic

force determines the output pressure. Therefore, the solenoid valve converts the

current signal into a pressure signal.

When it comes to automatic transmission, its driving convenience, power and comfort are more and more approved by consumers. The working principle and components of automatic transmission have also attracted more attention. The application of solenoid valve in automatic transmissions will be introduced in this article.

Hydraulics and solenoid valves in automatic transmissions

No matter it is a DCT, AT or CVT automatic transmission, the mainstream technical solutions are indispensable to the hydraulic system. The hydraulic system accepts the signal from controller, outputs oil pressure or flow, and acts on the actuator. The functions of hydraulic system mainly include: controlling the clutch, synchronizer or band pulley to reach the change of transmission ratio, controlling the state of torque converter clutch, and controlling the cooling and lubrication of the system. The performance of hydraulic system directly affects the smoothness of shifting and fuel economy of the entire vehicle, and is an important part of automatic transmission.

In the hydraulic system, the solenoid valve, which as an actuator, reaches the transformation from electrical signals to hydraulic signals, and controls the pressure and flow in the hydraulic system. It is a key component in the hydraulic system.

Classification and application of solenoid valve

The solenoid valve is divided into pilot control and direct drive control in the hydraulic system. The control pressure and flow of the pilot solenoid valve are relatively low, and the actuator cannot be directly driven, only the pilot control pressure is provided. The direct-drive solenoid valve has a larger electromagnetic force than the pilot valve, and control pressure and flow can directly drive the actuator. The hydraulic system using the direct-drive solenoid valve reduces the number of mechanical valves and simplifies the structure of system. Another solenoid valve product is the proportional electromagnet. Compared with other solenoid valves, the proportional electromagnet only has the electromagnetic part, which provides electromagnetic force. The hydraulic part is integrated on the hydraulic valve body. It is designed by customers according to the needs of the specific system. It has higher flexibility, but at the same time increases the integration difficulty of the hydraulic system.

Pilot control method: → Standard solenoid valve + mechanical valve

Advantage: Strong robustness

Disadvantage: 1. Many valves 2. Complex structure of system

Direct drive electromagnet control method: → Direct drive electromagnet + mechanical valve

Advantage: High flexibility

Disadvantage: Difficult integration

Direct drive electromagnet control method: → Solenoid valve drive actuator directly

Advantage: 1. Simple structure of system 2. High precision

Disadvantage: High cost

The introduction of proportional pressure regulator

Bleed type valve:

As shown in the figure below, the valve core is affected by hydraulic pressure, spring force and electromagnetic force. The balance state determines the valve core position, thereby determining the area of drain port. The pressure of control chamber at the left end depends on the input pressure, the input orifice and the area of the drain port determined by the variable adjustment surface. Therefore, the bleed valve achieves the effect of controlling the pressure by controlling the electromagnetic force. Since the Bleed valve regulates the pressure through overflow, the leakage of this valve is relatively large, and the control pressure is more sensitive to the fluctuation of input pressure.

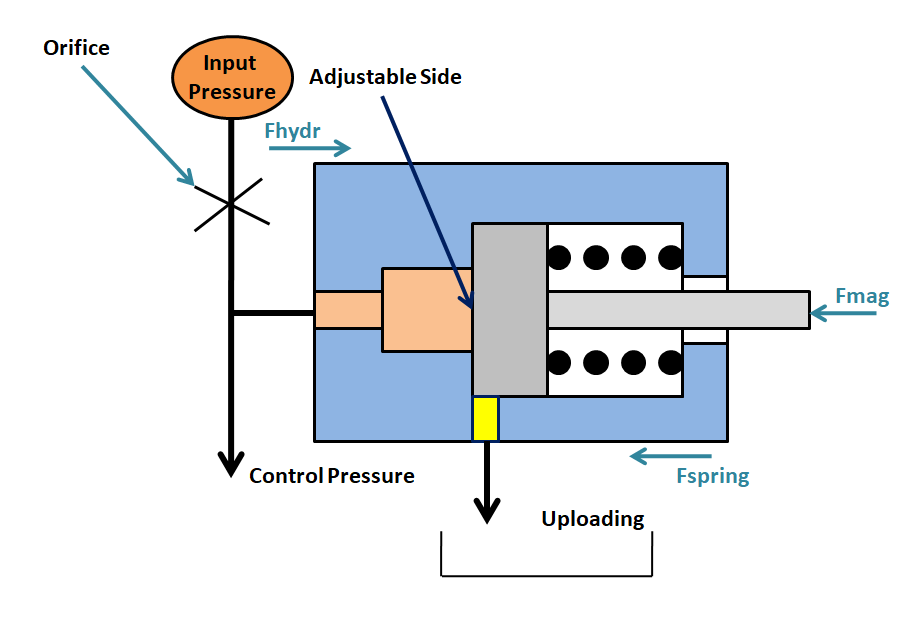

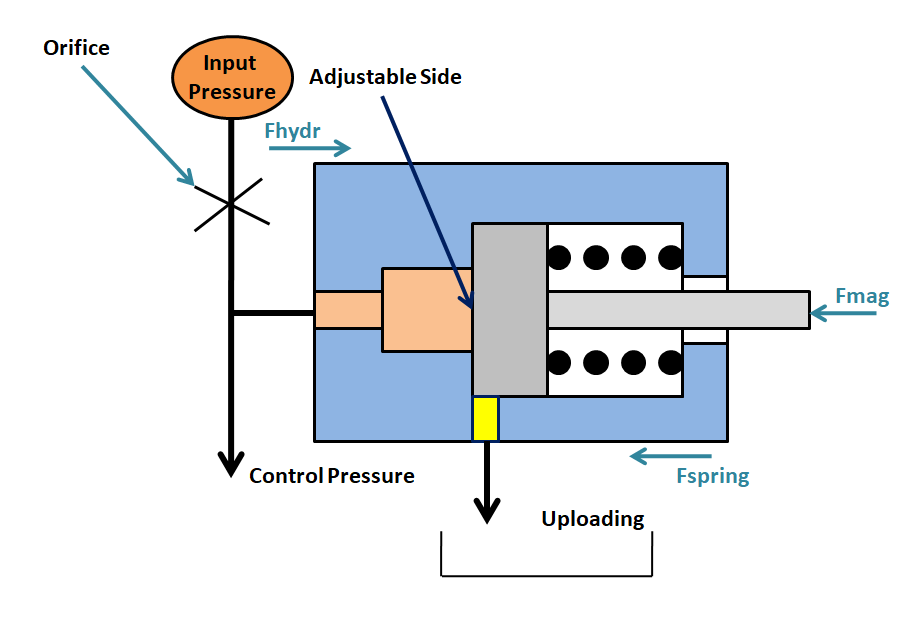

Spool type pressure valve:

As shown in the figure below, ignoring the influence of hydraulic power, the spool of

pressure valve is affected by the spring force, electromagnetic force and hydraulic

feedback force. Under the stable condition, the spool is in a balanced condition. The

electromagnetic force is positively related to the control current of solenoid valve.

Since the characteristics of the spring are fixed, in equilibrium, the electromagnetic

force determines the output pressure. Therefore, the solenoid valve converts the

current signal into a pressure signal.