Thermal Runaway Test Chamber of New Energy Battery

SHARE

MORE DETAIL

With the rapid development of new energy industry, various new energy batteries are playing an important role in the economy and society.

This also puts forward higher technical requirements for the use, storage and transportation of new energy batteries in low-voltage environments.

For example, the performance change thermal runaway propagation characteristics of new energy batteries in plateau areas and aircraft transportation are extremely important aspects of battery development. At present, the research on thermal runaway and performance change characteristics of new energy batteries in low-voltage environments mainly faces the following problems:

(1) The current thermal runaway testing equipment for new energy batteries mainly focuses on studying thermal runaway behavior under normal pressure. Research on the thermal runaway characteristics of batteries under environmental pressure is relatively lacking. More research on the impact of pressure changes on thermal runaway behavior still needs to be done.

(2) Studying characteristics of battery combustion and explosion behavior under varying environmental pressures is of particularly important reference significance for the early development, mid-term use and later prevention of thermal runaway of new batteries energy.

However, there is currently a lack of accurate simulation devices for changing environmental pressure. There are serious problems in the control method, which makes the environmental pressure control extremely unstable. It is difficult to accurately observe the changes in battery characteristics in pressure chamber, and the credibility of experiment is poor.

(3) In addition, hydrogen fuel cells, as a new energy battery, also have the above problems, and it is also necessary to verify the battery's operating performance and reliability spectrum under different altitude conditions. However, due to the particularity of hydrogen fuel cells, especially because hydrogen is a flammable and explosive gas, when the environmental pressure simulation equipment is running, the rotating machinery in the flow channel may generate sparks at high speed, which may then ignite the hydrogen and cause an explosion. This is absolutely not allowed for environmental simulation experimental equipment.

At the same time, hydrogen and air react in the fuel cell to form water, so the exhaust gas contains droplets. These droplets may cause damage to rotating parts when entering the equipment, affecting reliability of equipment. Therefore, for the environmental pressure simulation device of hydrogen fuel cells, these problems need to be avoided.

In response to the above-mentioned problems and needs in accurate control of environmental pressure in new energy batteries and hydrogen fuel cells, this article proposes corresponding solutions. The solutions mainly include the following two aspects:

(1) Technical transformation of the existing lithium battery environmental pressure simulation device, using the downstream control mode to reach programmable and accurate control of environmental pressure in simulation box, to meet the environmental pressure simulation needs of most new energy battery industry.

(2) Aiming at the environmental pressure simulation of hydrogen fuel cells, KaoLu’s Proportional Pressure Regulator can solve the problem!

How KaoLu’s Proportional Pressure Regulator solve the problem?

Lithium-ion batteries are prone to thermal runaway in high-temperature environments, which is dangerous and may catch fire or even explode. In order to provide simulated conditions of high temperature and environmental pressure for battery testing, the solution is to place the battery in a closed test environment box and control air pressure inside the environmental box to keep the battery at required environmental pressure.

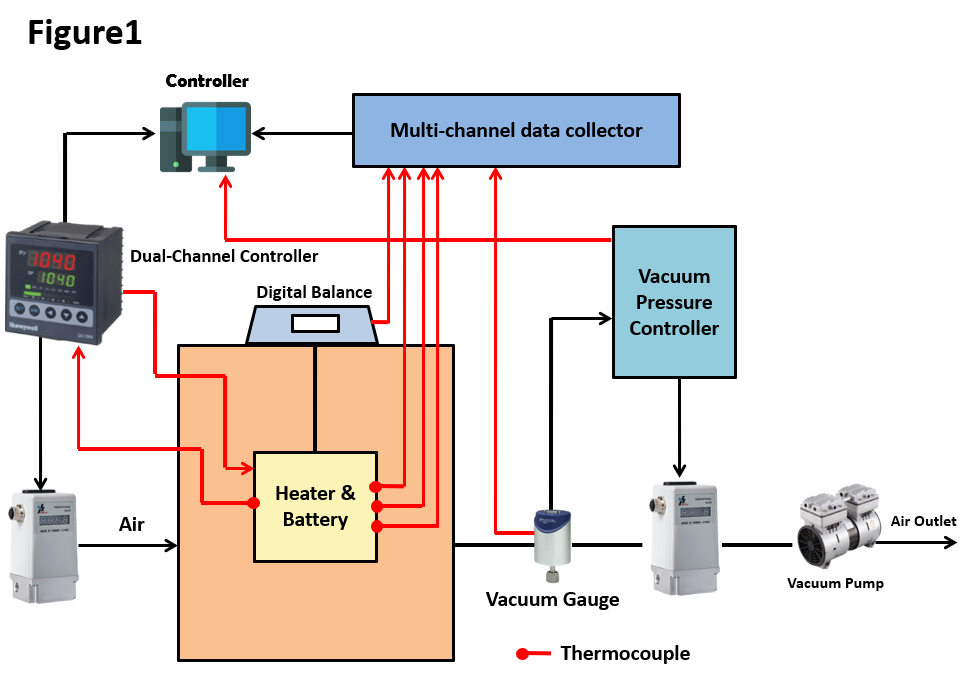

Then, the lithium-ion battery is externally heated to give the battery conditions for thermal abuse, and then the changes in parameters such as temperature and mass are studied through devices such as thermocouples and digital balances. The thermocouple measures the temperature change during the thermal runaway process, and the digital balance measures change in battery quality parameters during the thermal runaway process. The control system of the entire test device is shown in Figure 1.

As shown in Figure 1, the entire control system is mainly composed of an environmental pressure control loop, a battery heating temperature control loop, a quality measurement and a data acquisition device. Their respective functions and technical contents are as follows:

(1) Environmental pressure control loop

Its function is to control the programmable gas pressure of test environment box, and can automatically control a series of different set pressures. The control loop consists of KaoLu’s Proportional Pressure Regulator, a vacuum gauge, a vacuum pump, a vacuum pressure controller and a vacuum pipeline. One KaoLu’s Proportional Pressure Regulator controls inlet flow, the other KaoLu’s Proportional Pressure Regulator controls the exhaust flow, and the vacuum gauge measures vacuum degree in the environmental chamber. Also, transmitting to the controller, the controller compares the received vacuum signal with the set value and then drives the opening of KaoLu’s Proportional Pressure Regulator to change, and quickly makes the vacuum pressure in environmental box reach the set value. It should be noted that the control here adopts a downstream control mode in which the opening of intake Proportional Pressure Regulator is fixed and the opening of exhaust Proportional Pressure Regulator is changed. This can reach higher precision and stability of environmental pressure control.

(2) Battery heating temperature control loop

Its function is to heat and control the battery to simulate the temperature changes during battery thermal failure. The control loop consists of a heater, battery assembly, fixed splint, thermocouple temperature sensor and dual-channel controller. The thermocouple collects the battery temperature and transmits it to the controller. The controller compares the received temperature signal with set value before driving.

(3) Mass measurement device

Its function is to measure the mass loss of the battery body during the thermal runaway process. The quality measurement device is mainly a hanging digital balance. The digital balance placed outside the environmental box measures the battery quality through a suspension wire.

(4) Data acquisition device

Its function is to simultaneously collect battery temperature, environmental pressure and quality measurement data, display and store them in the form of curves. The data acquisition device mainly consists of a multi-channel data collector and a computer. The multi-channel data collector is connected to the corresponding temperature and pressure sensor and digital balance. The computer communicates with the collector and uses software to display and store the collection results.

It should be noted that in the solution, the computer can also communicate with the vacuum pressure controller and temperature controller, and perform parameter setting, operation control and control process parameter change curve display of controller through their respective software.

The battery environmental pressure simulation control system shown in Figure 1 is not suitable for hydrogen fuel cell performance testing. This is mainly because the mechanical rotary vacuum pump may generate sparks at high speed and ignite the hydrogen gas to cause an explosion. At the same time, the hydrogen fuel cell, water droplets will form in the vacuum pipeline, causing damage to the valves and rotating parts of the vacuum pump during the test.

To solve these two problems, the solution proposed in this article uses the following two technologies:

(1) Replace the vacuum pump with a vacuum generator, which uses high-pressure gas to create a vacuum. This can avoid spark ignition hazards caused by mechanical rotating parts.

(2) KaoLu’s Proportional Pressure Regulator has very good vacuum sealing performance, and the rotating part of motor is completely isolated from the passing gas, which will not cause ignition hazards.

To sum up, the solution can effectively realize the thermal runaway of various new energy batteries under variable environmental pressure and high temperature through improved ambient pressure downstream control technology, high-pressure gas vacuum generation technology and temperature automatic control technology. The solution has the following outstanding features:

(1) It can reach high-precision control of environmental pressure and temperature, which is more conducive to precise research and testing of battery characteristics.

(2) Environmental pressure and temperature control can be programmed and controlled according to different set values, and the entire process of battery characteristic testing can be automatically reached.

(3) KaoLu’s Proportional Pressure Regulator greatly reduces the workload of device construction.

More about KaoLu’s Proportional Pressure Regulator, please contact us for detailed information!