1.Soru

In the process of solvent extraction, the vacuum evaporation and concentration process is generally used. Since the solvent often has good volatility, the solvent is prone to loss during the vacuum extraction process, and sometimes the loss can reach 5~8%. Therefore, in order to solve the loss of solvent in the evaporation and concentration process, the following problems need to be solved:

(1) The precise control problem of vacuum degree, such as fixed-point control and program control, which is the key to reducing solvent loss.

(2) Simultaneous control problem of vacuum degree and temperature. This is because different vacuum degrees determine the boiling point of the solution. Through coordinated control of vacuum degree and temperature at the same time, the yield of the solvent can be greatly improved.

(3) In the vacuum evaporation and concentration process, many solvents and solutions are often corrosive to a certain extent, which requires the vacuum regulating valve to have good corrosion resistance. In order to solve the requirement of reducing solvent loss in the evaporation and concentration process, this article proposes a solution for precise control of vacuum degree, including the use of electronic flow control valve with strong corrosion resistance as vacuum degree control valves.

2. Solution

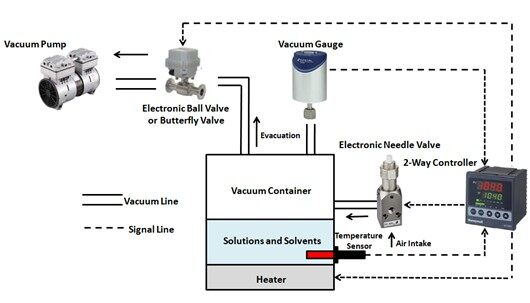

For the precise control of vacuum degree and temperature in the evaporation and concentration process, the overall structure of control system is shown in Figure 1.

(Figure 1 Schematic diagram of the vacuum degree and temperature control system structure of the evaporation and concentration process)

The basic principle of precise vacuum control is the dynamic control method, that is, according to the control set value and the measured value of vacuum gauge, the intake flow and exhaust flow of vacuum container are adjusted respectively, so that the flow in and out can reach a dynamic balance. If automatic control is required, PID control algorithms and corresponding controllers are required.

As shown in Figure 1, the accurate control proposal for vacuum degree control in this article adopts a dynamic control method, using an electronic flow control valve to adjust the intake flow, using an electronic ball valve or an electronic needle valve to adjust the exhaust flow, and the vacuum pump is used as a vacuum source. The automatic control of vacuum degree adopts PID controller.

In order to reach the temperature control function at the same time, this scheme adopts a dual-channel PID controller, one channel is used to control the vacuum degree, and another channel is used to control the temperature. This dual-channel PID controller is shown in Figure 2. This PID control has 24-bit A/D and 16D/A, with 47 input signal forms (thermocouple, thermal resistance, DC voltage), and can be connected to various vacuum and temperature sensors for measurement, display and control. It also has 2 independent measurement control channels, two-wire RS485, standard MODBUS RTU communication protocol.

(Figure 2 VPC2021 series dual-channel PID controller)

(Figure 3 FC series electronic needle valve)

In order to reach high-precision adjustment in the vacuum degree control process, an electronic needle valve with fine adjustment by a numerically controlled stepping motor is used, as shown in Figure 3. The hysteresis of this FC series proportional needle valves is much smaller than that of solenoid valves, and has a high-speed response within 1 second, especially the use of fluorine rubber (FKM) sealing technology, which makes the valve have superior corrosion resistance. Equipped with a stepper motor drive circuit module with the numerical control proportional needle valve, it provides the required power supply (24VDC) and control signal (0~10VDC) for the numerical control needle valve, and can also provide direct control of RS485 serial communication.

For larger-diameter air-extraction pipelines, a miniature proportional needle valve is used in this scheme, as shown in Figure 3. This series of proportional needle valve is a small electronic valve. The valve opening can be adjusted continuously according to the change of control signal (0~10VDC). The fastest opening and closing time is less than 7 seconds, and the opening and closing time can also reach less than 1 second. The integrated design of the valve and the valve body reduces external volume and is low in price. It is often installed between the sealed container and the vacuum pump to adjust pumping rate.

In short, through the solution described in this article, the vacuum degree control accuracy in the evaporation and concentration process can reach 1%, and the corresponding temperature control can also be carried out. The vacuum regulating valve has super corrosion resistance, which can effectively reduce the loss of solvent concentration during the vacuum evaporation process.