2022.03.02

FC Electric Needle Valve Introduction

SHARE

MORE DETAIL

Abstract: Compared with manually operated needle valve and proportional valve, electric needle valve has the characteristics of digital control, high sensitivity, fast response and small hysteresis. This article introduces the localized replacement products of smart electric needle valves developed against foreign products. This product not only features the same product performance but also the low cost high performance. Compared with similar domestic electric needle valves, it has the characteristics of small size and flexibility for secondary development and application. Also, when it combines with 24-bit ADC, it can achieve a precise flow rate regulation capability of electric needle valve.

1. Overview

The electric needle valve is a micro‑ adjustable valve with a needle-shaped valve shaft, which is mainly used for regulating air flow. The needle-shaped valve plug of the needle valve can make the lifting of the valve port gradually become larger, and can be continuously and meticulously regulated from the power up and down. As a valve that can be precisely regulated, the electric needle valve is widely used, and it is mainly used for meticulous adjustment and control of gas flow, vacuum level and pressure.

Some common methods to adjust needle position are hand wheels and handles, but in laboratory and industrial automation production processes, we usually require a digitally controlled needle valves that can be connected to computers and other control instruments. The opening of the needle valve can be regulated via digital programming control. Electric needle valves are used in many fields such as various high-precision analytical instruments, semiconductor process equipment, vacuum process equipment and high-precision flow control.

Otherwise, compared with the proportional valve, the electric needle valve has the characteristics of high sensitivity and small hysteresis. Therefore, in response to the market demand for electric needle valves, KaoLu has developed a series of electric needle valve driven by a stepper motor controller, which has the same technical index performance but a low cost high performance. Compared with similar localized electric needle valves, it has the characteristics of small size and flexibility for secondary development and application. Combining our FC series electric needle valve with a 24-bit ADC, it is possible to achieve an extremely high resolution of flow rate control.

2. Comparison of existing localized and foreign-made electric needle valve

2.1 Existing localized electric needle valve

At present, domestic electric needle valve generally adopts the structure of adding a conventional motor actuator to the standard needle valve. A typical product of this structure is shown in Figure 2-1. The electric needle valve with a motor actuator structure has the following characteristics:

- ①. The power supply voltage is generally AC 220V (or DC 24V), and the control signal is DC 0~10V (or 4~20mA).

- ②. Electric actuators for ball valves and butterfly valves are generally used for reference, resulting in huge volume.

- ③. The inherent turndown ratio is generally 50:1, so the adjustment and control accuracy is poor.

- ④. The adjustment response time is slow, and has a serious lag phenomenon. The switching time is at least 5 seconds.

- ⑤. The valve size is generally large, and the smallest can only reach “1/4”, which is more suitable for the adjustment and control of larger flow.

- ⑥. The whole pressure resistance is high, which is more suitable for the regulation and control of high pressure and large flow.

2.2 Existing foreign-made electric needle valve

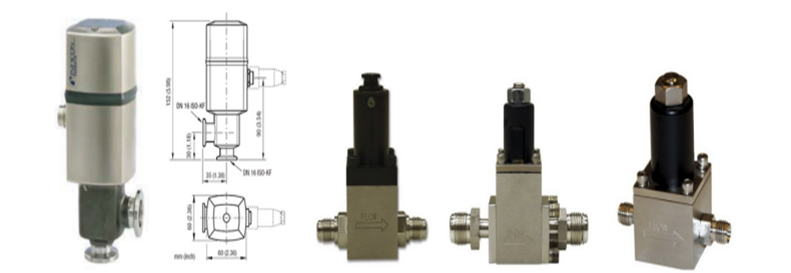

A typical foreign-made electric needle valves are the products of INFICON and MKS, as shown in Figure 2-2. The model of INFICON's product is VDE016, and the product of MKS is the "upstream flow control valve" series (including 148J, 154B and 248D).

The notable features of foreign-made electric needle valves are their small size and independent modules for drive control, which are very convenient for secondary development and use. Figure 2-3 is the main technical indicators of foreign-made electric needle valves.

| Model | INFICON VDE016-X | MKS 148J | MKS 154B | MKS 248D |

| Valve Type | Needle valve | |||

| Driver | Stepper Motor | Electromagnetic coil | ||

| Response Time (Open to close) |

3-4 sec | 15ms | / | 15ms |

| Standard Size | KF16 | VTF 1/4” | Swagelok 1/2” | Swagelok 1/4” |

| Contact Materials | Stainless steel | Stainless steel, PTEF etc. | Stainless steel etc. | Stainless steel |

| Pressure Range | 1×mbar | 10bar | / | 10bar |

| Flow Range | 3× ~75L/min | 0.01 ~ 30L/min | 0.2 ~ 200L/min | 0.1 ~ 50L/min |

| Linearity | / | |||

| Flow Resolution | / | 0.1 ~ 0.2% of Full scale | 0.1% of Full scale | 0.1 ~ 2% of Full scale |

| Appearance Size (mm) | 60×60×152 | 85×38×100 | / | 70×38×85 |

| Operating Temperature Range | 5 ~ 40c | 15 ~ 50c | -10 ~ 60c | |

| Seal | FPM | Metal | Elastic material | |

| Control Signal | DC 0 ~ 10V or RS232 | DC 0 ~ 10V or 4 ~ 20mA | ||

| Power Supply | DC24V (12W) | DC15 ~ 24V | ||

From the above technical indicators, we can know that only INFICON electric needle valve adopts the stepper-controlled method, while the products of MKS are basically typical needle solenoid valves, and solenoid valves generally have a large hysteresis phenomenon.(Figure 2-3 Main technical indicators of foreign-made electric needle valves.)

Compared with the current price, the electric needle valve of INFICON equipped with a drive circuit module, and the overall price is about 20,000 CNY. The main product currently promoted by MKS is 248D. Its price is about 8,000 CNY, and it needs to be equipped with a drive circuit module. ( about 5,000 CNY), the total price is around 13,000 CNY.

3. KaoLu electric needle valve

The FC electric needle valve developed by KaoLu is a smart electronic two-way metering needle valve, which changes the diameter structure of the traditional manual needle valve and adopts a high-precision linear stepper motor to drive the valve shaft. The electric needle valve and its internal structure are shown in Figure 3-1.

The resolution of the stepper-controlled proportional valve driver is 0.0127mm/step and 0.0254/step. The low differential pressure valve can operate continuously (100% duty ratio). A power outage is the normally closed position of FC electric needle valve.

The biggest advantage of stepper-controlled motor drive mode compared to solenoid valve is cooling operation, which means no control operation problems due to coil heating, extremely high resolution, extremely low differential pressure and high operating pressure. The valve can be controlled by DC 12 VDC compatible logic levels and analog 0 to 2.5 VDC signals, or using the RS485 inter face by direct communication. The resulting benefits are a hysteresis of less than 2%, excellent linearity of less than 2.5% of full scale, a 2ms response time and a lifetime of millions of times. Please visit https://www.genndih.com/proportional-flow-control-valve.htm

| Model | FC-20 | FC-120 | FC-300 | FC-1000 |

| Valve Type | Needle valve | |||

| Driver | Bipolar stepper motor control | |||

| Response Time | 0.8sec (Open to close) | |||

| Standard Size | G 1/8” | G 3/8” | ||

| Fluid | Inert gas and liquid | |||

| Pressure Range | -1 ~ 7 bar | -1 ~ 5 bar | ||

| Flow Range | 3× ~75L/min | 0.01 ~ 30L/min | 0.2 ~ 200L/min | 0.1 ~ 50L/min |

| Maximum Flow | 50L/min @7bar | 240L/min @7bar | 290L/min @7bar | 600L/min @7bar |

| Linearity | 2% | 0.1 ~ 1% | 0.2 ~ 5% | 11% |

| Repeatability (Full scale) |

1% | |||

| Flow Resolution (Step length) | 0.1L | 0.1 ~ 0.2L | 0.2 ~ 0.75L | 1L |

| Shift Resolution | 12.7 um | 25.4 um | ||

| Operating Temperature Range | 0 ~ 84c | |||

| Seal | Standard FKM or other choices of seals | |||

| Control Signal | DC: 0 ~ 10V (or 4 ~ 20mA) | |||

| Power Supply | DC: 24V (12W) | |||

(Figure 3-2 Main technical indicators of electric needle valves.)

FC series of electric needle valve is equipped with a stepper motor drive circuit module to provide the required power supply and control signal, and to convert the DC signal into the stepper control of the bipolar stepper motor. It also provides RS485 serial port communication direct control. The drive circuit module, wiring method and size are shown in Figure 3-3.

4. Conclusion

To sum up, the FC electric needle valve developed by KaoLu adopts the most advanced stepper motor drive dynamic technology, technical indicators and exceed foreign products, also has low cost high performance.