2020.12.07

Type 100 Precision Air Pressure Regulator Explained: Why this unit does not allow “0” PSI of output

SHARE

MORE DETAIL

Type 100 Precision Air Pressure Regulator

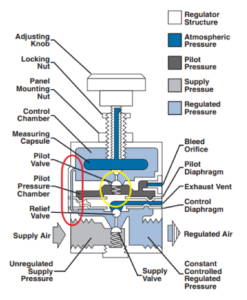

The Type 100 Precision Air Pressure Regulator is our most accurate offering. The designed-in bleed orifice and measuring capsule allows this unit to remain in a reactive state and make incredibly small internal adjustments.

High Precision Air Pressure Regulator

The Type 100 uses a measuring capsule which ever so slightly expands and contracts with changing output pressure. This measuring capsule is essential to achieving a very high level of precision. When downstream pressure slightly decreases, the capsule (which is filled with atmospheric pressure) expands to apply additional downward force to the pilot valve which increases the pressure in the pilot chamber. This increased force opens the supply valve slightly to increase output pressure. The opposite happens when downstream pressure increases and the capsule contracts.

The capsule sits in a control chamber which is surrounded by output pressure. There is a channel (circled in red) in the device which feeds this chamber with output pressure. The startup spring (circled in yellow) acts as the force on the supply valve that constantly keeps it slightly open and does not allow the unit to go to 0 PSI. The pressure is usually about 1 psi and can be thought of as start up or primer pressure as it primes the device with moving air. Without this spring, this unit would be able to achieve a 0 PSI output. However, if this unit did not have this spring, the device would now rely on supply pressure to feed the control chamber.

If the control chamber was fed with supply pressure instead of primer pressure, the capsule would not contribute to the control of the unit and the output pressure would ultimately increase until output pressure matched supply pressure. In a low-pressure range device, the measuring capsule would actually be crushed by the force of the supply pressure.

In cases where you need to maintain a high level of output accuracy but also be able to shut off supply, we would recommend installing an on/off valve upstream of the unit or a solenoid to shut off supply pressure.