2022.02.10

Atmosphere Pressure Control in Vacuum Laser Powder Bed Fusion

SHARE

MORE DETAIL

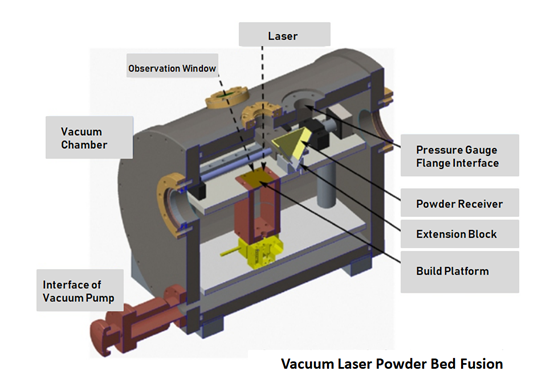

Precise Pressure Control in Vacuum Laser Powder Bed Fusion

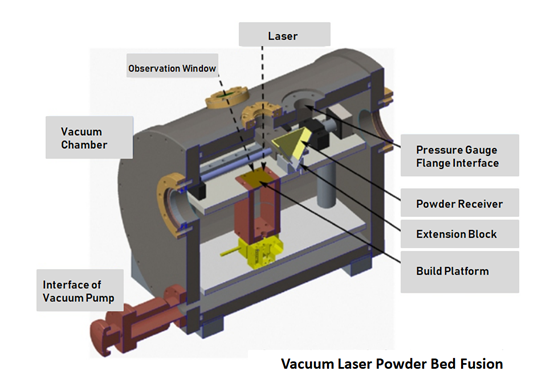

Low pressure SLM fusion process in laser powder bed fusion

Features: The molten pool is more stable and reduces porosity. Low-pressure atmosphere requirements: Fast and accurate air pressure control is reached within the process window of 5kPa~101kPa.

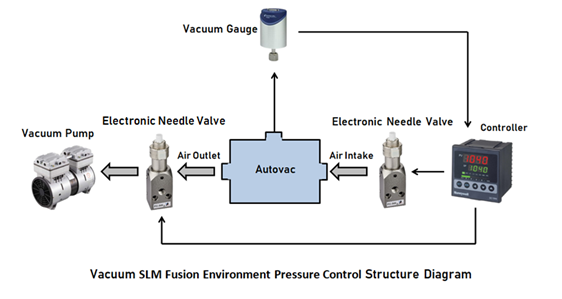

Pressure Control

Control method: two-way control method, adjusting upstream air intake using electronic air flow control valve and downstream secondary proportional flow contro valve at the same time. It can also adjust the air intake flow and vacuum pump exhaust rate. This will materialise an high accuracy vacuum level control in laser powder bed fusion. For further information on electronic air flow control valve, please visit https://www.genndih.com/proportional-flow-control-valve.htm

Sensor: vacuum pressure sensor, the measurement range is 5kPa~101kPa, and the accuracy is ±0.2%.

Controller: two-way PID controller, two-way control function

Low pressure SLM fusion process in laser powder bed fusion

Features: The molten pool is more stable and reduces porosity. Low-pressure atmosphere requirements: Fast and accurate air pressure control is reached within the process window of 5kPa~101kPa.

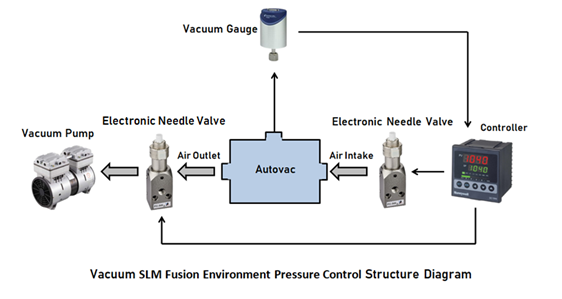

Pressure Control

Control method: two-way control method, adjusting upstream air intake using electronic air flow control valve and downstream secondary proportional flow contro valve at the same time. It can also adjust the air intake flow and vacuum pump exhaust rate. This will materialise an high accuracy vacuum level control in laser powder bed fusion. For further information on electronic air flow control valve, please visit https://www.genndih.com/proportional-flow-control-valve.htm

Sensor: vacuum pressure sensor, the measurement range is 5kPa~101kPa, and the accuracy is ±0.2%.

Controller: two-way PID controller, two-way control function