SHARE

MORE DETAIL

1. Introduction of proportional valve

Proportional valves allow faster, easier and more precise control of the duty cycle and meet the performance requirements of the switching process, are controlled during the switching process, and avoid excessive peak pressures, thus extending the lifetime of mechanical and hydraulic device elements.

Proportional valves can be divided into: proportional pressure regulator, proportional flow valve, proportional directional valve, proportional valve, which are high-precision pneumatic components, and have requirements for hydraulic oil and installation methods.

2. Installation requirements of proportional valve

(1) The proportional valve must check the model and other data before installing.

(2) The cleanliness of hydraulic oil is required. When the proportional valve is installed, the installation environment and valve body must be clean, and oil tank must also be sealed to prevent the intrusion of external pollutants.

(3) The hydraulic oil pipe and oil tank should be cleaned of dust, oxide scale, sand, metal chips and other debris before installing.

(4) Hot elbows and welded pipes must be pickled, rinsed with clean water and oiled.

(5) Only use lint-free non-woven fabric or special paper when cleaning.

(6) It is not allowed to use sealing materials such as hemp, putty or sealing tape for sealing.

(7) Hydraulic pipelines must be made of seamless steel pipes conforming to DIN2391/C standards.

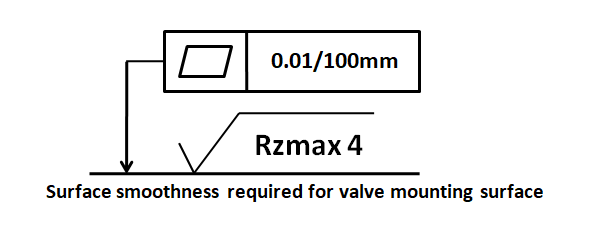

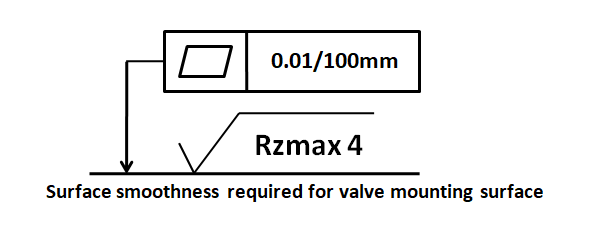

(8) The pipeline between proportional valve and actuator should be as short as possible to increase the rigidity of system. It is recommended that the proportional valve be installed near the actuator, and the surface roughness of installation plane should not be greater than Rz=4μm and flatness less than 0.01/100mm.

(9) Due to the relatively high precision requirements of proportional valve, in order to ensure the better rigidity of system, the use of a hose connection between proportional valve and actuator should be avoided.

(10) Selection of air filter, it is recommended to use an oil-immersed filter with a mesh size of less than 60 microns as an air filter.

(11) Requirements for the installation position of proportional valve

The installation position of proportional valve can be optional, and it is recommended to be the horizontal position. If proportional valve is installed on actuator, the axis of spool should be avoided, and it should be parallel to the acceleration direction of actuator, which will affect the displacement accuracy of spool.

3. Requirements for the use of proportional valves

(1) Pay attention to the applicable range of pressure and temperature of proportional valve, and comply with the regulations of related products.

(2) The oil temperature of hydraulic oil should not exceed the maximum operating temperature recommended by oil manufacturer. In order to ensure the stability of the control characteristics of equipment, it is recommended to keep the oil temperature basically constant within plus or minus 5 degrees.

(3) Filtration requirements, in order to prolong the service life, the pilot control valve should use a 10μm imported oil filter, or it can be selected according to the accuracy given in sample.

The allowable differential pressure of the oil filter must be greater than the actual differential pressure. Oil filters with contamination indicators are recommended. When replacing the oil filter, special attention must be paid to cleanliness. Contaminants on the outlet side of the new oil filter will be flushed into the system, causing accidents. The pollutants on the inlet side of the oil filter will reduce the life of the filter element.

(4) The control pressure of pilot valve should not be greater than 30bar. If the pilot pressure exceeds 100Bar, a plate type pressure reducing valve must be installed at the inlet. In order to avoid the pressure shock of fuel tank pipeline, a check valve must be used.

(5) Storage requirements, the storage environment should be dry and dust-free, free of corrosive substances and water vapor. When the storage time exceeds three months, the proportional valve housing should be coated with anti-rust oil and sealed.

Proportional valves allow faster, easier and more precise control of the duty cycle and meet the performance requirements of the switching process, are controlled during the switching process, and avoid excessive peak pressures, thus extending the lifetime of mechanical and hydraulic device elements.

Proportional valves can be divided into: proportional pressure regulator, proportional flow valve, proportional directional valve, proportional valve, which are high-precision pneumatic components, and have requirements for hydraulic oil and installation methods.

2. Installation requirements of proportional valve

(1) The proportional valve must check the model and other data before installing.

(2) The cleanliness of hydraulic oil is required. When the proportional valve is installed, the installation environment and valve body must be clean, and oil tank must also be sealed to prevent the intrusion of external pollutants.

(3) The hydraulic oil pipe and oil tank should be cleaned of dust, oxide scale, sand, metal chips and other debris before installing.

(4) Hot elbows and welded pipes must be pickled, rinsed with clean water and oiled.

(5) Only use lint-free non-woven fabric or special paper when cleaning.

(6) It is not allowed to use sealing materials such as hemp, putty or sealing tape for sealing.

(7) Hydraulic pipelines must be made of seamless steel pipes conforming to DIN2391/C standards.

(8) The pipeline between proportional valve and actuator should be as short as possible to increase the rigidity of system. It is recommended that the proportional valve be installed near the actuator, and the surface roughness of installation plane should not be greater than Rz=4μm and flatness less than 0.01/100mm.

(9) Due to the relatively high precision requirements of proportional valve, in order to ensure the better rigidity of system, the use of a hose connection between proportional valve and actuator should be avoided.

(10) Selection of air filter, it is recommended to use an oil-immersed filter with a mesh size of less than 60 microns as an air filter.

(11) Requirements for the installation position of proportional valve

The installation position of proportional valve can be optional, and it is recommended to be the horizontal position. If proportional valve is installed on actuator, the axis of spool should be avoided, and it should be parallel to the acceleration direction of actuator, which will affect the displacement accuracy of spool.

3. Requirements for the use of proportional valves

(1) Pay attention to the applicable range of pressure and temperature of proportional valve, and comply with the regulations of related products.

(2) The oil temperature of hydraulic oil should not exceed the maximum operating temperature recommended by oil manufacturer. In order to ensure the stability of the control characteristics of equipment, it is recommended to keep the oil temperature basically constant within plus or minus 5 degrees.

(3) Filtration requirements, in order to prolong the service life, the pilot control valve should use a 10μm imported oil filter, or it can be selected according to the accuracy given in sample.

The allowable differential pressure of the oil filter must be greater than the actual differential pressure. Oil filters with contamination indicators are recommended. When replacing the oil filter, special attention must be paid to cleanliness. Contaminants on the outlet side of the new oil filter will be flushed into the system, causing accidents. The pollutants on the inlet side of the oil filter will reduce the life of the filter element.

(4) The control pressure of pilot valve should not be greater than 30bar. If the pilot pressure exceeds 100Bar, a plate type pressure reducing valve must be installed at the inlet. In order to avoid the pressure shock of fuel tank pipeline, a check valve must be used.

(5) Storage requirements, the storage environment should be dry and dust-free, free of corrosive substances and water vapor. When the storage time exceeds three months, the proportional valve housing should be coated with anti-rust oil and sealed.

For further information about KaoLu's electronic pressure regulator, please visit https://www.genndih.com/proportional-pressure-regulator.htm