SHARE

MORE DETAIL

1. Introduction of KaoLu's Electronic Vacuum Regulator

In vacuum pressure control process of some mechanical grasping and closed cavities, it is necessary to directly use regulating valve to reach the precise adjustment and constant control of vacuum degree. KaoLu QKL series is a kind of this vacuum regulating valve, which is manually operated and adjusted. The nominal vacuum adjustment range is absolute pressure 1.3~100kPa (gauge pressure -100~-1.3kPa).

In order to have a deeper understanding of KaoLu's Electronic Vacuum Regulator, this article introduces the short-term assessment test of vacuum degree control stability of this Electronic Vacuum Regulator.

2. Let's Talk About KaoLu's Electronic Vacuum Regulator!

The action principle of KaoLu's Electronic Vacuum Regulator is as follows: When the handwheel turns clockwise, the spring force is set to push the diaphragm and the main valve downward, the VAC side and the SET side are connected, and vacuum degree of SET side changes to direction of low pressure.

Then, the vacuum pressure on SET side enters vacuum chamber through air path, acts on top of diaphragm, and is balanced with the compression force of setting spring, so vacuum pressure on SET side is kept constant. If air pressure on SET side is lower than set value, the setting spring force and pressure on SET side of vacuum chamber are out of balance. The diaphragm is pulled up, the main valve core is closed, air suction valve core is opened, and air flows into SET side. When the compression force and air pressure on SET side are balanced, the vacuum pressure on the SET side is kept constant.

The nominal vacuum adjustment range of KaoLu's Electronic Vacuum Regulator is absolute pressure 1.3~100kPa (gauge pressure -100~-1.3kPa).

3. To Examine The Function of KaoLu's Electronic Vacuum Regulator

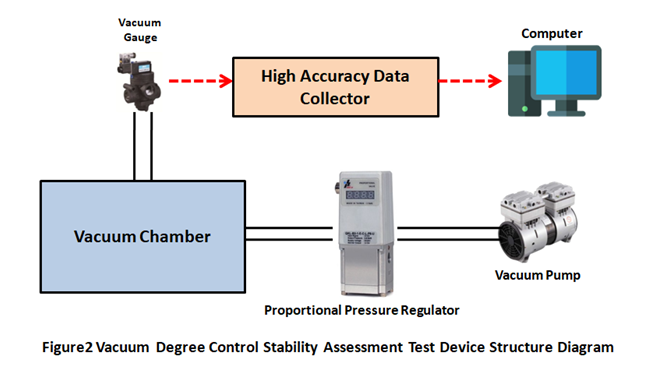

In order to assess the performance indicators of the KaoLu's Electronic Vacuum Regulator, the assessment test device built is shown in Figure 2, which mainly includes a vacuum pump, a vacuum chamber, a capacitance vacuum gauge, a high-precision data collector and a computer. In order to accurately measure the vacuum adjustment range and the stability of control, each component in assessment test device has some characteristics:

- The vacuum chamber is a closed chamber, that is, the leakage rate is very low, and the vacuum pipeline only has two interfaces, a vacuum gauge and a regulating valve.

- The vacuum degree measurement adopts a thin-film capacitor vacuum gauge with high precision. The accuracy is 0.25% under any vacuum degree, and the range of vacuum degree measurement is 1 to 1000Torr.

- In order to make full use of measurement accuracy of capacitance vacuum gauge, the assessment device is equipped with high-precision data collector, and uses supporting software to communicate with computer to collect and display vacuum measurement curve in real time. In order to ensure the acquisition accuracy and speed at the same time, the sampling interval is set to 4s.

- In order to avoid pollution of vacuum pump oil to pipeline and vacuum regulating valve, the assessment device is specially equipped with a dry pump to ensure a varierty of pollution.

4. Conclusion

From the above short-term assessment test results, the following conclusions can be drawn:

- Within the full vacuum range, the constant fluctuation of vacuum is better than ±0.5%.

- The adjustment and control time is affected by volume of vacuum chamber, the smaller the volume, the faster the vacuum degree will stabilize.

- KaoLu's Electronic Vacuum Regulator reach the nominal technical index -100kPa.

Please refer to KaoLu's website for further information.