SHARE

MORE DETAIL

With the development of economy and the improvement of people's living standards, more and more attention has been paid to the technological development in the field of food production, storage, transportation and processing. Vacuum thawing and derived vacuum sublimation-rehydration thawing technology is one of these new food processing technologies.

Vacuum thawing technology uses the characteristics of different pressures in a vacuum state and different boiling points of water. The water vapor formed when water boils in a vacuum chamber will condense into water droplets on the surface of frozen food at a lower temperature. The latent heat released when the steam condenses is absorbed by the frozen food, and finally the temperature of the frozen product rises to thaw.

Comparing with other thawing methods, vacuum thawing has the advantages of fast thawing rate, uniform thawing effect, and low thawing temperature. Moreover, the frozen products are in a vacuum and low-oxygen environment during the thawing process, which can effectively inhibit the oxidation of food and reproduction of some aerobic microorganisms, also reduce the loss of quality.

With the advancement of technology, a new method based on vacuum thawing technology has emerged: vacuum sublimation-rehydration thawing method. The biggest feature of this method is that it can be extended and applied to the thawing process of other frozen foods such as fruits, vegetables, cooked food, and aquatic products.

In summary, one of the important advantages of vacuum thawing and vacuum sublimation-rehydration thawing methods is that the thawing parameters (temperature and vacuum) can be optimized according to the characteristics of frozen products and energy consumption, so as to reach the best thawing state.

In order to solve the problem that vacuum degree in vacuum freezing process cannot be programmed and automatically and accurately controlled, a specific solution is proposed in this article.

The basic principle of the solution is to use KaoLu’s Proportional Pressure Regulator to adjust air intake flow according to different vacuum pressure settings according to the dynamic balance method, and finally reach the thawing vacuum degree of various frozen products at any setting. Accurate program control is carried out at fixed points, thus making the vacuum thawing technology more widely applicable and quality assurance ability.

2. Principle of dynamic balance method for vacuum pressure control

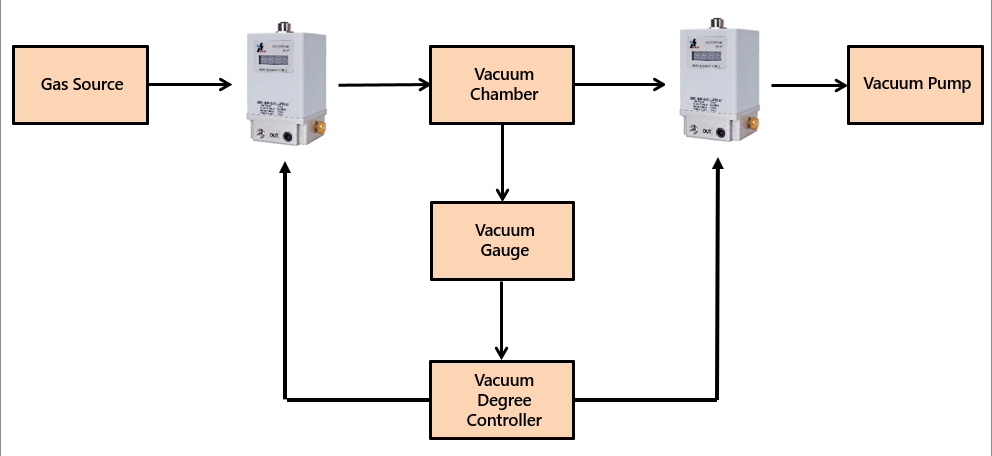

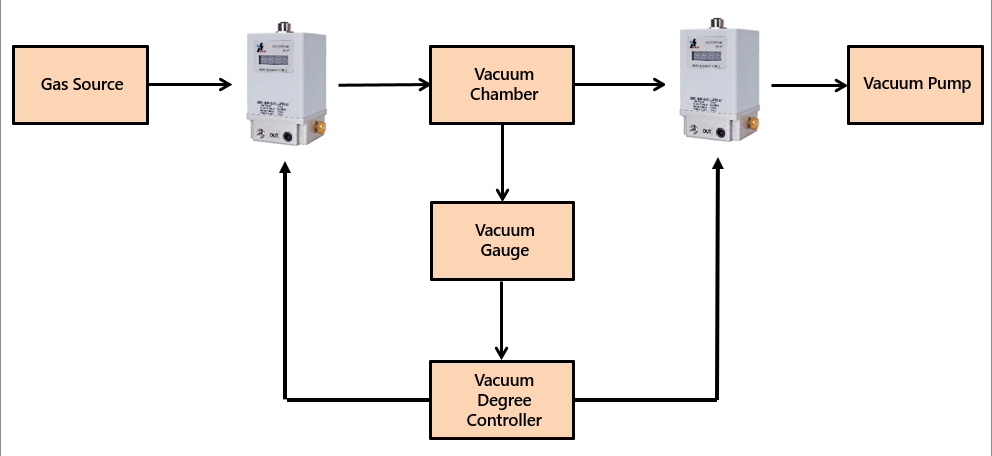

In the vacuum pressure control process, the most common precision control method is the dynamic balance method, as shown in Figure 3, its basic principle is based on the dynamic balance between the intake flow and exhaust flow, thereby reaching the accurate adjustment of different vacuum pressure settings control.

(Schematic diagram of the principle of dynamic balance method for vacuum pressure control)

3. Solution

The working process of vacuum control system is that the dual-channel vacuum pressure controller compares the signal collected from the vacuum gauge according to vacuum degree set value or set program. The controller uses the PID algorithm to calculate and output the control signal according to the difference after comparison, and the control signal drives KaoLu’s Proportional Pressure Regulator to dynamically adjust air intake or exhaust flow, so that the vacuum degree in vacuum chamber changes, which makes the measured value of vacuum gauge approach to the set point for automatic control immediately. The description of each component of vacuum degree control system in the solution is as follows:

(1) Although the existing vacuum gauge can be used, in order to ensure the control accuracy of vacuum degree, it is recommended that vacuum gauge adopt a high-precision thin-film capacitance vacuum gauge, and its measurement accuracy at any vacuum degree can be better than 0.3%.

In addition, in order to meet the vacuum thawing of various frozen products, it is necessary to control the vacuum degree in a wider range of vacuum degrees, so it is recommended to use two capacitance vacuum gauges with different ranges to cover them. The recommended ranges of the two vacuum gauges are 1Torr and 10Torr.

(2) The vacuum degree control system adopts KaoLu’s Proportional Pressure Regulator to adjust the intake and exhaust flow respectively. KaoLu’s Proportional Pressure Regulator combined with two vacuum gauges with high and low ranges, can reach a control accuracy better than 1% within the full vacuum range. In addition, in order to ensure control accuracy and vacuum stability, KaoLu’s Proportional Pressure Regulator need to meet certain leak rate and response speed requirements.

(3) Another key instrument in the vacuum control system is a high-precision dual-channel vacuum pressure controller. Its independent two-way PID control channel forms a high-vacuum control channel with a 1Torr vacuum gauge and an electric needle valve, and a 10Torr vacuum gauge. It forms a low vacuum control channel with the electric ball valve. The important thing is that each independent channel is 24-bit AD, 16-bit DA and 0.01% minimum output percentage, which can ensure precise control of vacuum pressure.

In addition, this controller has the PID parameter self-tuning function, which can quickly reach the reasonable selection of PID parameters. It is equipped with a standard RS485 communication interface and computer software, which is convenient for communication with the host computer and using the host computer for control parameter setting, operation, and process variables. Acquisition, display, storage and recall.

In short, the vacuum degree control solution proposed in this article can well meet all the requirements for automatic and accurate control of vacuum degree in the vacuum thawing process, and is very suitable for laboratory vacuum thawing process research and vacuum thawing equipment for processing a large number of frozen products.

Want to know more about KaoLu's Proportional Pressure Regulator? Welcome you to visit KaoLu's website!

Vacuum thawing technology uses the characteristics of different pressures in a vacuum state and different boiling points of water. The water vapor formed when water boils in a vacuum chamber will condense into water droplets on the surface of frozen food at a lower temperature. The latent heat released when the steam condenses is absorbed by the frozen food, and finally the temperature of the frozen product rises to thaw.

Comparing with other thawing methods, vacuum thawing has the advantages of fast thawing rate, uniform thawing effect, and low thawing temperature. Moreover, the frozen products are in a vacuum and low-oxygen environment during the thawing process, which can effectively inhibit the oxidation of food and reproduction of some aerobic microorganisms, also reduce the loss of quality.

With the advancement of technology, a new method based on vacuum thawing technology has emerged: vacuum sublimation-rehydration thawing method. The biggest feature of this method is that it can be extended and applied to the thawing process of other frozen foods such as fruits, vegetables, cooked food, and aquatic products.

In summary, one of the important advantages of vacuum thawing and vacuum sublimation-rehydration thawing methods is that the thawing parameters (temperature and vacuum) can be optimized according to the characteristics of frozen products and energy consumption, so as to reach the best thawing state.

In order to solve the problem that vacuum degree in vacuum freezing process cannot be programmed and automatically and accurately controlled, a specific solution is proposed in this article.

The basic principle of the solution is to use KaoLu’s Proportional Pressure Regulator to adjust air intake flow according to different vacuum pressure settings according to the dynamic balance method, and finally reach the thawing vacuum degree of various frozen products at any setting. Accurate program control is carried out at fixed points, thus making the vacuum thawing technology more widely applicable and quality assurance ability.

2. Principle of dynamic balance method for vacuum pressure control

In the vacuum pressure control process, the most common precision control method is the dynamic balance method, as shown in Figure 3, its basic principle is based on the dynamic balance between the intake flow and exhaust flow, thereby reaching the accurate adjustment of different vacuum pressure settings control.

(Schematic diagram of the principle of dynamic balance method for vacuum pressure control)

3. Solution

The working process of vacuum control system is that the dual-channel vacuum pressure controller compares the signal collected from the vacuum gauge according to vacuum degree set value or set program. The controller uses the PID algorithm to calculate and output the control signal according to the difference after comparison, and the control signal drives KaoLu’s Proportional Pressure Regulator to dynamically adjust air intake or exhaust flow, so that the vacuum degree in vacuum chamber changes, which makes the measured value of vacuum gauge approach to the set point for automatic control immediately. The description of each component of vacuum degree control system in the solution is as follows:

(1) Although the existing vacuum gauge can be used, in order to ensure the control accuracy of vacuum degree, it is recommended that vacuum gauge adopt a high-precision thin-film capacitance vacuum gauge, and its measurement accuracy at any vacuum degree can be better than 0.3%.

In addition, in order to meet the vacuum thawing of various frozen products, it is necessary to control the vacuum degree in a wider range of vacuum degrees, so it is recommended to use two capacitance vacuum gauges with different ranges to cover them. The recommended ranges of the two vacuum gauges are 1Torr and 10Torr.

(2) The vacuum degree control system adopts KaoLu’s Proportional Pressure Regulator to adjust the intake and exhaust flow respectively. KaoLu’s Proportional Pressure Regulator combined with two vacuum gauges with high and low ranges, can reach a control accuracy better than 1% within the full vacuum range. In addition, in order to ensure control accuracy and vacuum stability, KaoLu’s Proportional Pressure Regulator need to meet certain leak rate and response speed requirements.

(3) Another key instrument in the vacuum control system is a high-precision dual-channel vacuum pressure controller. Its independent two-way PID control channel forms a high-vacuum control channel with a 1Torr vacuum gauge and an electric needle valve, and a 10Torr vacuum gauge. It forms a low vacuum control channel with the electric ball valve. The important thing is that each independent channel is 24-bit AD, 16-bit DA and 0.01% minimum output percentage, which can ensure precise control of vacuum pressure.

In addition, this controller has the PID parameter self-tuning function, which can quickly reach the reasonable selection of PID parameters. It is equipped with a standard RS485 communication interface and computer software, which is convenient for communication with the host computer and using the host computer for control parameter setting, operation, and process variables. Acquisition, display, storage and recall.

In short, the vacuum degree control solution proposed in this article can well meet all the requirements for automatic and accurate control of vacuum degree in the vacuum thawing process, and is very suitable for laboratory vacuum thawing process research and vacuum thawing equipment for processing a large number of frozen products.

Want to know more about KaoLu's Proportional Pressure Regulator? Welcome you to visit KaoLu's website!