2022.06.05

Superconducting Gravity Instruments Ultra-Fine Temperature and Pressure Control Solution

SHARE

MORE DETAIL

Superconducting Gravity Instruments - Ultra-Fine Temperature (0.1mK) and Pressure Control Solution

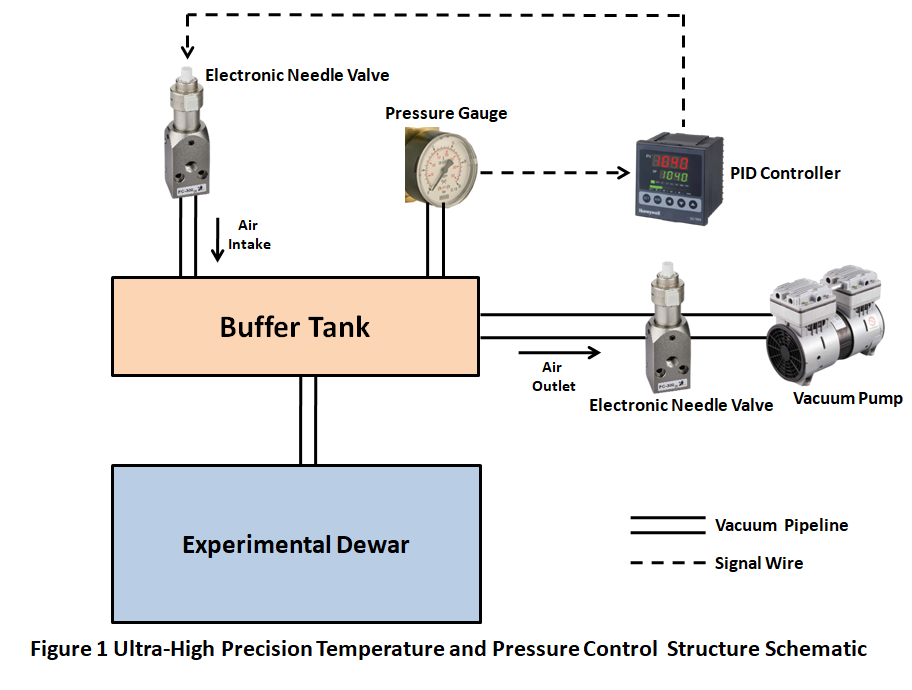

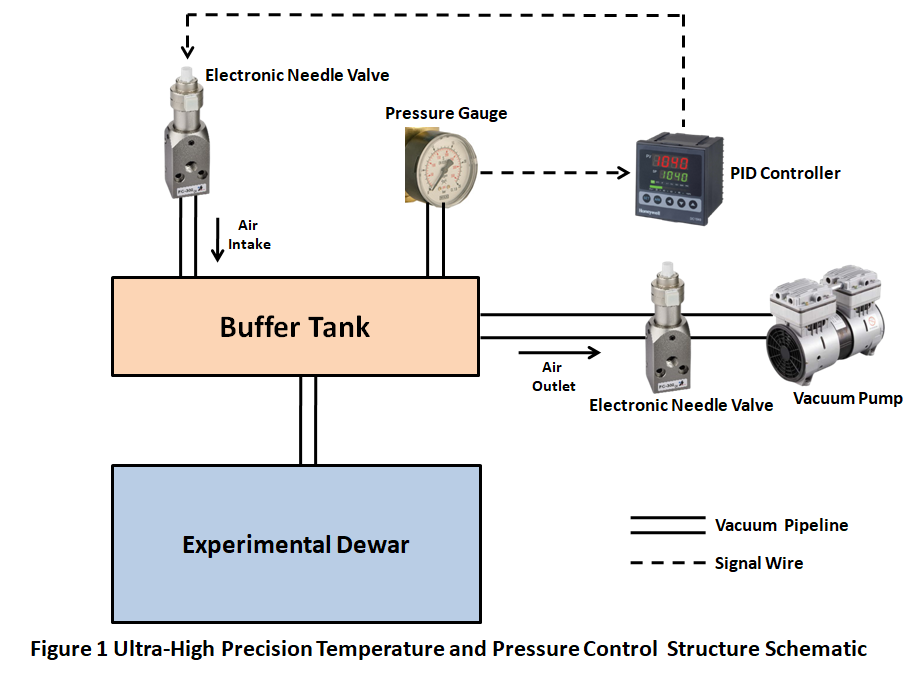

The temperature of liquid helium pool is required to be constant in the ultra-low gravity instrument. In order to reach the fluctuation degree of less than 0.1mK, the fluctuation degree of air pressure control should be less than 10Pa. For this reason, this article focuses on a corresponding technical scheme in superconducting gravity instruments. The core content is to reach the precise control of air pressure of buffer tank. The bidirectional control mode is adopted, and the air pressure sensor, electronic needle valve and PID controller with a precision of 1/10,000 are used.

1. Question

Superconducting gravity instruments include superconducting gravimeters and superconducting gravity gradiometers, both of which are used to precisely measure gravity signals.

Superconducting gravity instruments need to measure extremely weak signals at low temperature, so there is a high requirement for constant low temperature, that is, the temperature fluctuation of liquid helium pool is required to be within 0.1mK.

The precise control of temperature of liquid helium pool in superconducting gravity instruments can be reached by controlling the air pressure in liquid helium pool, which requires the measurement and control of air pressure to reach a very high level. In this article, a corresponding solution is proposed for the high-precision control of air pressure in liquid helium cell in the superconducting gravity instrument. The advantage of this solution is that the control accuracy of temperature of liquid helium pool is mainly affected by the accuracy of pressure sensor. The ultra-high-precision pressure sensor is selected, and the downstream pumping flow control mode is adopted through the precise numerical control needle valve and the high-precision PID controller. The fluctuation of liquid helium temperature is stably controlled within 0.1mK.

2. Technical Scheme

The precise control principle of liquid helium temperature in superconducting gravity instruments is based on the relationship between the saturated vapor pressure of liquid helium and the corresponding temperature. According to the corresponding relationship between the saturated vapor pressure of liquid helium and the temperature, the temperature of liquid helium should be controlled at about 4K, and the temperature fluctuation should be less than 0.1mK. When the upper pressure of liquid helium should be controlled at about 100kPa, the fluctuation of pressure should be less than 10Pa.

In order to reach the above air pressure control accuracy, the technical solution proposed in this article specifically in superconducting gravity instruments includes the following aspects:

(1) The air pressure control in the upper part of liquid helium pool can be abstracted as the pressure control in a closed container. For the pressure control of the closed container, it is necessary to add a buffer tank, through the pressure control of buffer tank. The system reaches the pressure control of liquid helium pool, and the structure is shown in Figure 1.

(2) The pressure control of buffer tank adopts the upstream and downstream two-way control mode, which is controlled by adjusting the flow of air intake and exhaust.

(3) The whole control system includes buffer tank, air pressure sensor, PID controller, digital needle valve and vacuum pump.

(4) If the air pressure is controlled at 100kPa and the fluctuation is required to be less than 10 Pa, the measurement and control of the air pressure are required to have an accuracy of 10/100k=0.0001 (one ten thousandth), so it is necessary to be equipped with a precision of one ten thousandth Barometer and PID controller.

In short, the control accuracy of technical solution described in this article is mainly limited by the accuracy of air pressure sensor and the PID controller. Combined with the small flow electronic needle valve driven by the stepping motor, the superconducting gravimeter can be reached through the high-precision sensor and controller. Precise control of liquid helium temperature, temperature fluctuation can be controlled within 0.1mK, and is not affected by changes in external ambient temperature.

For further information on the proportional flow control valve, please visit

https://www.genndih.com/proportional-flow-control-valve.htm