2022.03.28

Rapid and Precise Control Technology of Vacuum Degree and Temperature in Vacuum Pulse braised Process

SHARE

MORE DETAIL

Rapid and Precise Control Technology of Vacuum Degree and Temperature in Vacuum Pulse Halogenation Process

Abstract: Braised products are traditional food, and vacuum pulse process can effectively improve quality and shorten production time,and is more and more widely used in development and production of braised products. Focusing on the rapid and precise control requirements for the important process parameter of vacuum degree in the new vacuum pulse process, this article introduces the complete solution and implementation content in detail using FC series proportional flow control valve.

1. Question

As a traditional and nutritious food, braised products are deeply loved by public and are instant food for leisure and tourism. The current braised product manufacturing process is mainly divided into two categories: traditional braised method and vacuum drying method, and the new vacuum pulse braised method have outstanding characteristics. Compared with traditional braised method, vacuum pulse braised method can not only shorten the braised period. It can shorten time from 8 hours to 80 minutes, greatly improve the production efficiency, retain the food flavor, and can also reduce the content of microorganisms by 4 orders of magnitude, thus the product safety is greatly improved.

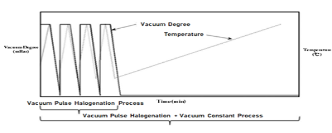

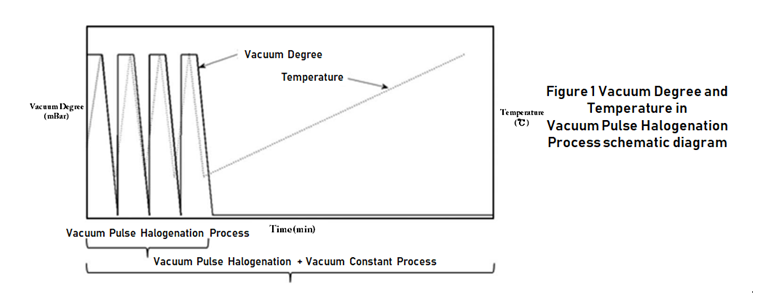

The typical vacuum pulse process is shown in Figure 1. The vacuum pulse process has high requirements on equipment and requires precise control of two important parameters (vacuum degree and temperature) in the braising process. The specific requirements are as follows:

(1) Real-time measurement of vacuum degree and temperature can be reached at the same time, and precise control is implying according to the set program. Therefore, the controller needs to have at least two independent signal acquisition and control functions.

(2) As shown in Figure 1, it is necessary to accurately control vacuum degree and temperature according to the upper and lower limits of setting vacuum degree and temperature and the corresponding change speed. This is equivalent to require the controller to have accurate program curve control capabilities.

This article focus on corresponding solutions for the above requirements, and will introduce integrated vacuum and temperature controllers that can be used in vacuum pulse braised processes, and introduce corrosion-resistant FC proportional flow control valve driven by stepper motors for gas flow regulation, which can well meet the precise control requirements of vacuum pulse braised process.

2. Vacuum pulse braised process control scheme

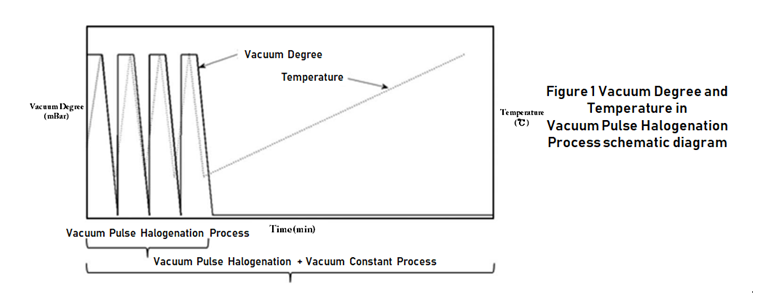

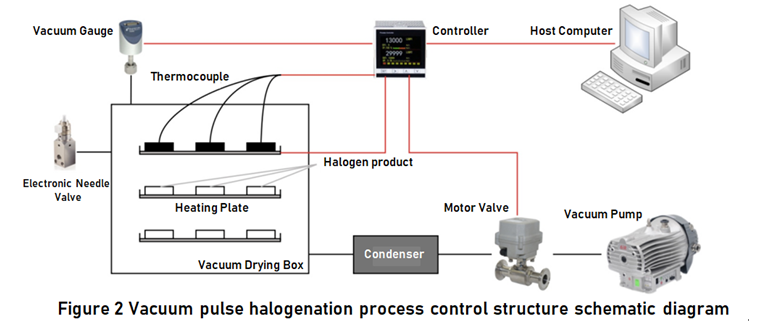

The vacuum degree and temperature need to be precisely controlled in the vacuum pulse braised process, and the specific control system implementation is shown in Figure 2.

In the vacuum degree control process shown in Figure 2, a method different from the previous vacuum degree control method is adopted, that is, an air intake channel is added to the vacuum chamber, multi-channel controller and a numerical control needle valve with fast response time and high precision are used. This program has two outstanding features:

(1) It can reach precise control of vacuum degree in the range of 0.1~1000mBar, and has a fluctuation rate of less than ±1% in the whole range. The specific implementation is that when the vacuum degree is less than 10torr, the control adopts the upstream mode; when the vacuum degree is greater than 10torr, the control adopts the downstream mode. At the same time, fast-response proportional flow control valves and controls ensure that temperature changes have minimal effect on vacuum.

(2) The equipped 2-channel integrated PID controller can reach the simultaneous control of vacuum degree, temperature and tunable speed. 2 independent channels for vacuum and temperature measurement, control and display.

(3) The host computer can communicate with the controller in real time to design, edit, store and load various vacuum degree and temperature control process curves.

3. 24-bit high-precision multi-functional controller

In order to reach the precise control of vacuum degree, temperature and rotation speed in vacuum microwave drying, KaoLu has developed FC series 24-bit high-precision programmable PID universal controller, as shown in Figure 2. This series of PID controllers are very useful and cost-effective.

The main performance indicators of VPC series controllers are as follows:

(1) Precision: 24-bit A/D, 16-bit D/A.

(2) Maximum sampling speed: 50ms.

(3) Various input parameters: 47 input signals (thermocouple, thermal resistance, DC voltage) can be connected to various temperature and vacuum sensors for measurement, display and control.

(4) Various output forms: 16BIT analog signal, 2A (250V AC) relay, 22V/20mA solid state relay, 3A/250VAC SCR.

(5) Multi-channel: independent 1-channel or 2-channel output. 2 channels can reach simultaneous measurement and control of temperature and vacuum degree, and the alarm output channel can be used to control the start-stop of rotating motor.

(6) Multi-function: forward, reverse, forward and reverse bi-directional control, heating/cooling control.

(7) PID program control: The improved PID algorithm supports PV differential and differential advance control. It can store 20 groups of PID and support 20 program curves (50 segments each).

(8) Communication: Two-wire RS485, standard MODBUS RTU communication protocol.

(9) Display mode: digital hall and IPS TFT true color LCD.

(10) Software: The operation of controller and the data acquisition and storage can be reached through the software computer. (11) Dimensions: 96×96×87mm (hole size 92×92mm).

4. Stepper motor drives corrosion-resistant high-speed needle valve

In order to reach high-precision adjustment in the process of vacuum degree control, KaoLu has developed a series of proportional control flow valves with different flow rates based on the needle valve using stepper motors, as shown in Figure 2. The magnetic hysteresis of this series is much smaller than solenoid valves, and has a high-speed response within 1 second. In particular, the use of FKM sealing technology enables the valve to have superior corrosion resistance. The detailed technical indicators are shown in Figure 4 shown.

(Figure 5 Technical indicators of KaoLu’s FC electronic needle valve)

For further information, please visit https://www.genndih.com/proportional-flow-control-valve/mid-flow-proportional-valve-0-130L-min.html

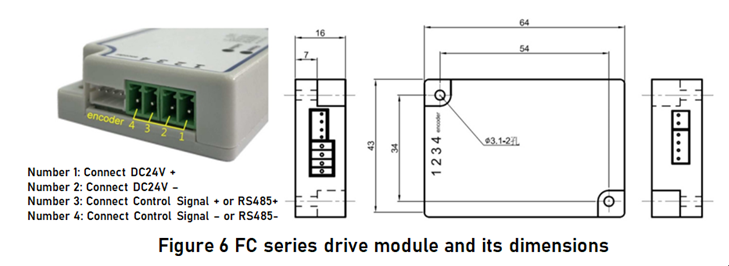

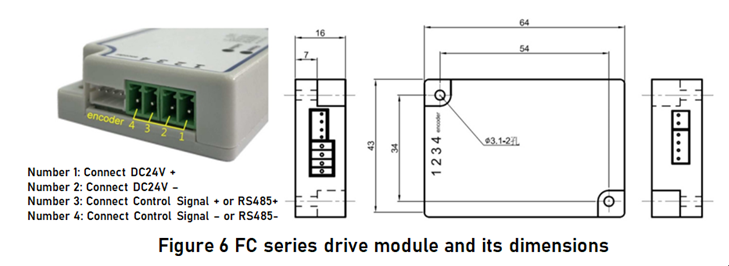

FC proportional control flow valve is equipped with a stepper motor drive circuit module, which provides the required power supply and control signal for FC proportional control flow valve, and converts the DC signal into step control of bipolar stepper motor, and can also provide RS485 direct control of serial communication. Its specifications and dimensions are shown in Figure 5.

When using proportional flow control valve in vacuum microwave drying, open-loop control method can also be used to install needle valve at the front end of vacuum pump instead of electric ball valve, and the vacuum degree can be controlled by adjusting pumping flow, but the stability of this open-loop control method is poor. It is difficult to reach higher stability requirements. Therefore, it is generally recommended to use closed-loop control method shown in Figure 1, that is, to add an air intake control valve to vacuum chamber, and to achieve precise control of vacuum degree by adjusting air intake flow and exhaust flow at the same time. Using KaoLu’s proportional flow control valve can help with achieving the desired function.

Abstract: Braised products are traditional food, and vacuum pulse process can effectively improve quality and shorten production time,and is more and more widely used in development and production of braised products. Focusing on the rapid and precise control requirements for the important process parameter of vacuum degree in the new vacuum pulse process, this article introduces the complete solution and implementation content in detail using FC series proportional flow control valve.

1. Question

As a traditional and nutritious food, braised products are deeply loved by public and are instant food for leisure and tourism. The current braised product manufacturing process is mainly divided into two categories: traditional braised method and vacuum drying method, and the new vacuum pulse braised method have outstanding characteristics. Compared with traditional braised method, vacuum pulse braised method can not only shorten the braised period. It can shorten time from 8 hours to 80 minutes, greatly improve the production efficiency, retain the food flavor, and can also reduce the content of microorganisms by 4 orders of magnitude, thus the product safety is greatly improved.

The typical vacuum pulse process is shown in Figure 1. The vacuum pulse process has high requirements on equipment and requires precise control of two important parameters (vacuum degree and temperature) in the braising process. The specific requirements are as follows:

(1) Real-time measurement of vacuum degree and temperature can be reached at the same time, and precise control is implying according to the set program. Therefore, the controller needs to have at least two independent signal acquisition and control functions.

(2) As shown in Figure 1, it is necessary to accurately control vacuum degree and temperature according to the upper and lower limits of setting vacuum degree and temperature and the corresponding change speed. This is equivalent to require the controller to have accurate program curve control capabilities.

This article focus on corresponding solutions for the above requirements, and will introduce integrated vacuum and temperature controllers that can be used in vacuum pulse braised processes, and introduce corrosion-resistant FC proportional flow control valve driven by stepper motors for gas flow regulation, which can well meet the precise control requirements of vacuum pulse braised process.

2. Vacuum pulse braised process control scheme

The vacuum degree and temperature need to be precisely controlled in the vacuum pulse braised process, and the specific control system implementation is shown in Figure 2.

In the vacuum degree control process shown in Figure 2, a method different from the previous vacuum degree control method is adopted, that is, an air intake channel is added to the vacuum chamber, multi-channel controller and a numerical control needle valve with fast response time and high precision are used. This program has two outstanding features:

(1) It can reach precise control of vacuum degree in the range of 0.1~1000mBar, and has a fluctuation rate of less than ±1% in the whole range. The specific implementation is that when the vacuum degree is less than 10torr, the control adopts the upstream mode; when the vacuum degree is greater than 10torr, the control adopts the downstream mode. At the same time, fast-response proportional flow control valves and controls ensure that temperature changes have minimal effect on vacuum.

(2) The equipped 2-channel integrated PID controller can reach the simultaneous control of vacuum degree, temperature and tunable speed. 2 independent channels for vacuum and temperature measurement, control and display.

(3) The host computer can communicate with the controller in real time to design, edit, store and load various vacuum degree and temperature control process curves.

3. 24-bit high-precision multi-functional controller

In order to reach the precise control of vacuum degree, temperature and rotation speed in vacuum microwave drying, KaoLu has developed FC series 24-bit high-precision programmable PID universal controller, as shown in Figure 2. This series of PID controllers are very useful and cost-effective.

The main performance indicators of VPC series controllers are as follows:

(1) Precision: 24-bit A/D, 16-bit D/A.

(2) Maximum sampling speed: 50ms.

(3) Various input parameters: 47 input signals (thermocouple, thermal resistance, DC voltage) can be connected to various temperature and vacuum sensors for measurement, display and control.

(4) Various output forms: 16BIT analog signal, 2A (250V AC) relay, 22V/20mA solid state relay, 3A/250VAC SCR.

(5) Multi-channel: independent 1-channel or 2-channel output. 2 channels can reach simultaneous measurement and control of temperature and vacuum degree, and the alarm output channel can be used to control the start-stop of rotating motor.

(6) Multi-function: forward, reverse, forward and reverse bi-directional control, heating/cooling control.

(7) PID program control: The improved PID algorithm supports PV differential and differential advance control. It can store 20 groups of PID and support 20 program curves (50 segments each).

(8) Communication: Two-wire RS485, standard MODBUS RTU communication protocol.

(9) Display mode: digital hall and IPS TFT true color LCD.

(10) Software: The operation of controller and the data acquisition and storage can be reached through the software computer. (11) Dimensions: 96×96×87mm (hole size 92×92mm).

4. Stepper motor drives corrosion-resistant high-speed needle valve

In order to reach high-precision adjustment in the process of vacuum degree control, KaoLu has developed a series of proportional control flow valves with different flow rates based on the needle valve using stepper motors, as shown in Figure 2. The magnetic hysteresis of this series is much smaller than solenoid valves, and has a high-speed response within 1 second. In particular, the use of FKM sealing technology enables the valve to have superior corrosion resistance. The detailed technical indicators are shown in Figure 4 shown.

| Model | FC-20 | FC-120 | FC-300 | FC-1000 |

| Valve type | Needle Valve | |||

| Spool Drift Diameter | 0.9mm | 2.25mm | 2.75mm | 4.10mm |

| Actuator | Bipolar stepper motor control | |||

| Response time | 0.8sec(Open to close) | |||

| Standard size | G1/8” | G3/8” | ||

| Fluid | Inert gas and liquid | |||

| Contact Materials | Stainless Steel | |||

| Pressure Range | -1 ~ 7bar | -1 ~ 5bar | ||

| Maximum Flow | 50L/min @7bar | 240L/min @7bar | 290L/min @7bar | 600L/min @7bar |

| Linearity | ±2% | ±0.1 ~ 1% | ±0.2 ~ 5% | ±11% |

| Repeatability (Full scale) |

±0.1% | |||

| Flow Resolution (Step length) |

0.1L/min | 0.1 ~ 0.2L/min | 0.2 ~ 0.75L/min | 1L/min |

| Shift Resolution (Step length) | 12.7um | 25.4um | ||

| Operating Temperature Range | 0 ~ 84°c | |||

| Seal | Standard FKM or other choices of seals | |||

| Control Signal | DC: 0 ~ 10V (or 4 ~ 20mA) | |||

| Power Supply | DC: 24V (12W) | |||

For further information, please visit https://www.genndih.com/proportional-flow-control-valve/mid-flow-proportional-valve-0-130L-min.html

FC proportional control flow valve is equipped with a stepper motor drive circuit module, which provides the required power supply and control signal for FC proportional control flow valve, and converts the DC signal into step control of bipolar stepper motor, and can also provide RS485 direct control of serial communication. Its specifications and dimensions are shown in Figure 5.

When using proportional flow control valve in vacuum microwave drying, open-loop control method can also be used to install needle valve at the front end of vacuum pump instead of electric ball valve, and the vacuum degree can be controlled by adjusting pumping flow, but the stability of this open-loop control method is poor. It is difficult to reach higher stability requirements. Therefore, it is generally recommended to use closed-loop control method shown in Figure 1, that is, to add an air intake control valve to vacuum chamber, and to achieve precise control of vacuum degree by adjusting air intake flow and exhaust flow at the same time. Using KaoLu’s proportional flow control valve can help with achieving the desired function.